ARG-US Remote Monitoring Systems: Use Cases and Applications in Nuclear Facilities and During Transportation

As highlighted in the Spring 2024 issue of Radwaste Solutions, researchers at the Department of Energy’s Argonne National Laboratory are developing and deploying ARG-US—meaning “Watchful Guardian”—remote monitoring systems technologies to enhance the safety, security, and safeguards (3S) of packages of nuclear and other radioactive material during storage, transportation, and disposal.

This work supports the DOE’s Office of Environmental Management’s Office of Packaging and Transportation mission of “seeking to protect people and the environment by ensuring the safe, compliant, and efficient transportation of materials critical to successful department operations,” as well as benefits those working in nuclear fuel cycle facilities and nuclear cargo conveyance and storage industries.

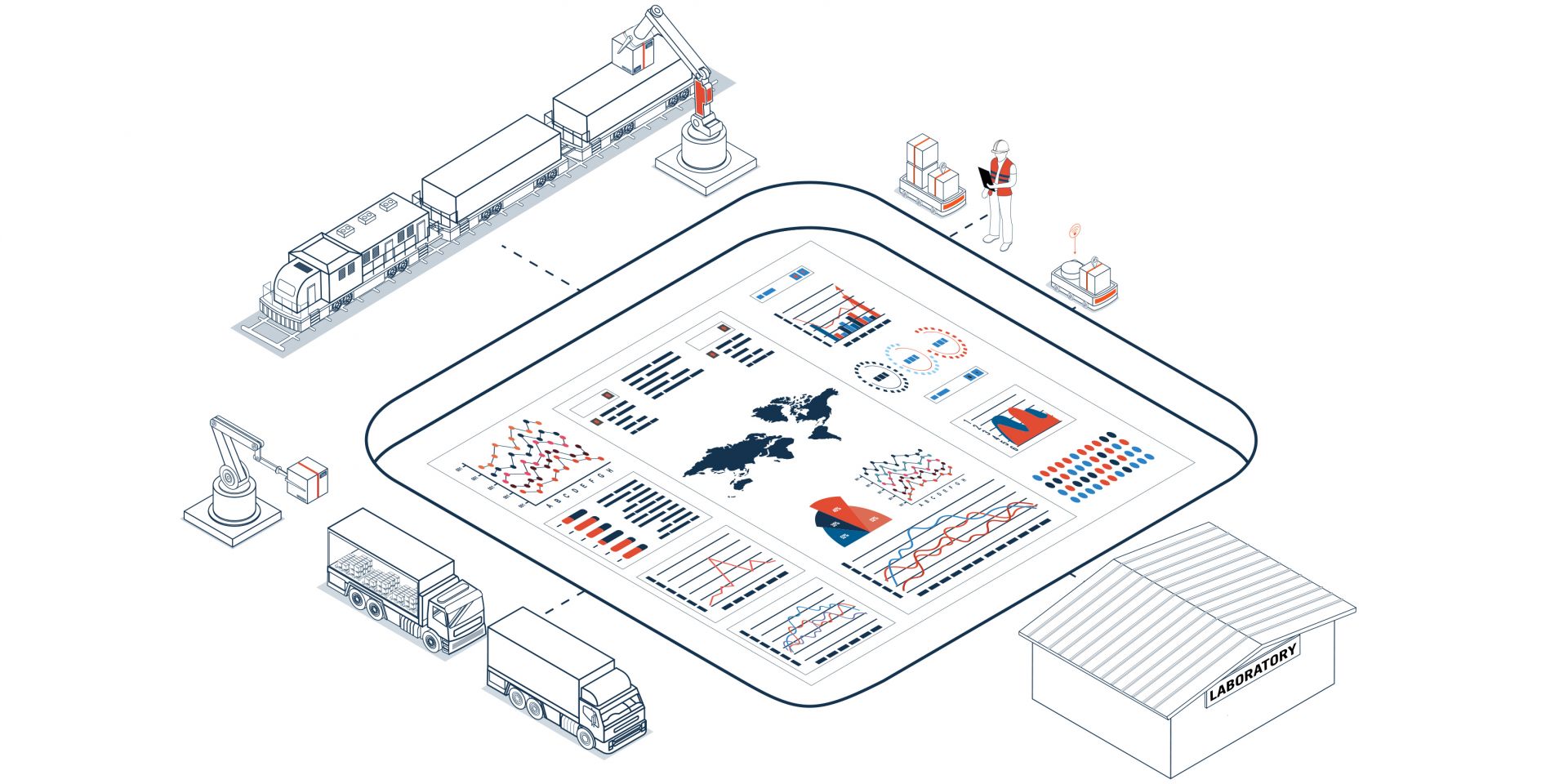

The ARG-US remote monitoring systems technologies consist of two patented platforms. The first is radio-frequency identification (RFID) surveillance tags with sensors for drum-type packages in storage and transportation with fixed and handheld readers, or an “all-in-one” CommBox. The second is remote area modular monitoring (RAMM) systems for nuclear fuel cycle facilities and the TRAVELER, for real-time tracking and monitoring of packages of nuclear fuel cycle materials in operating conveyances.

ARG-US RFID systems work by using active RFID sensor surveillance tags with sensors that are attached to drum-type packages in storage or transportation. “Smart drums,” which are drums equipped with RFID tags and readers (illustrated above in Fig. 1), enhance 3S and materials accountability and reduce the exposure of personnel to radiation to as low as reasonably achievable (ALARA). Smart drums also provide authorized personnel with real-time access to status and event history data, as well as continuous monitoring of environmental conditions during operations.

The overall benefit of the technology is significant. In applications at nuclear facilities and during transportation, ARG-US RFID technologies would enhance 3S performance with tremendous cost-effectiveness.

Use cases and applications

Since 2010, five DOE laboratories (Argonne National Laboratory, Idaho National Laboratory, Oak Ridge National Laboratory, Sandia National Laboratories, Savannah River National Laboratory) and two sites (Savannah River Site and Nevada National Security Site), as well as industry, have acquired the ARG-US RFID and RAMM systems for field testing, demonstrations, and applications. This article describes six use cases and applications spanning over 10 years: three in nuclear facilities at Argonne and three in transportation.

Continuing operation and continual application of the ARG-US remote monitoring systems in these facilities and during transportation should help drive adoption and implementation of ARG-US systems technologies in other DOE nuclear facilities and industry sites, including advanced reactor nuclear fuel cycles in the future.

Facilities

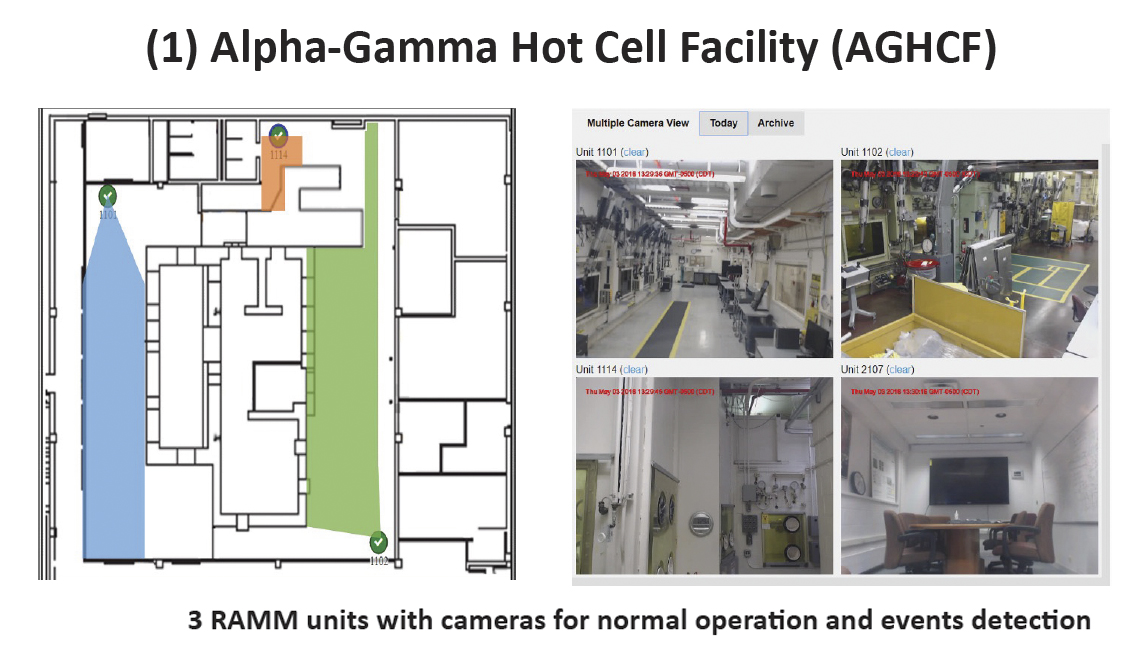

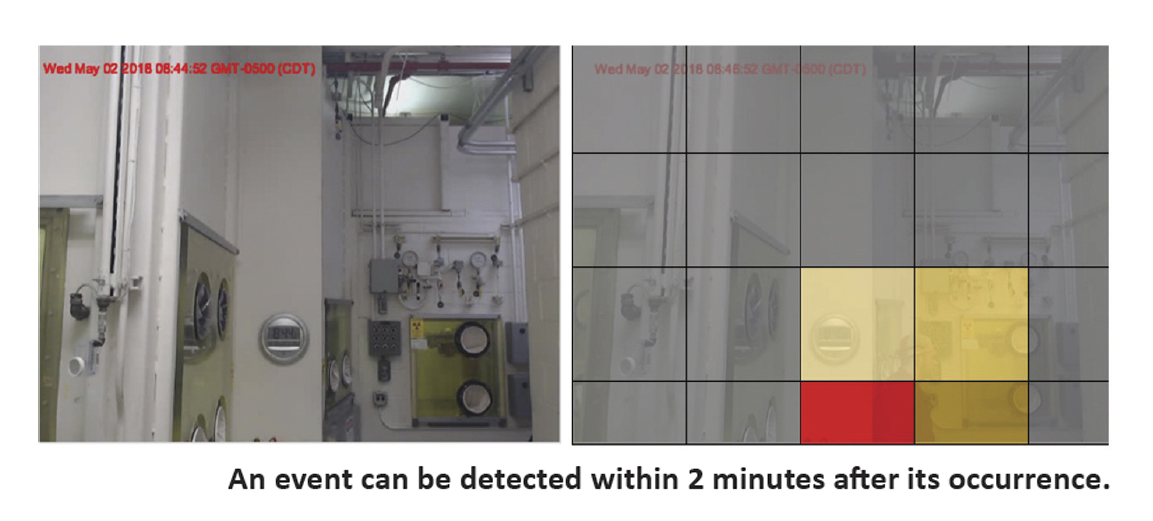

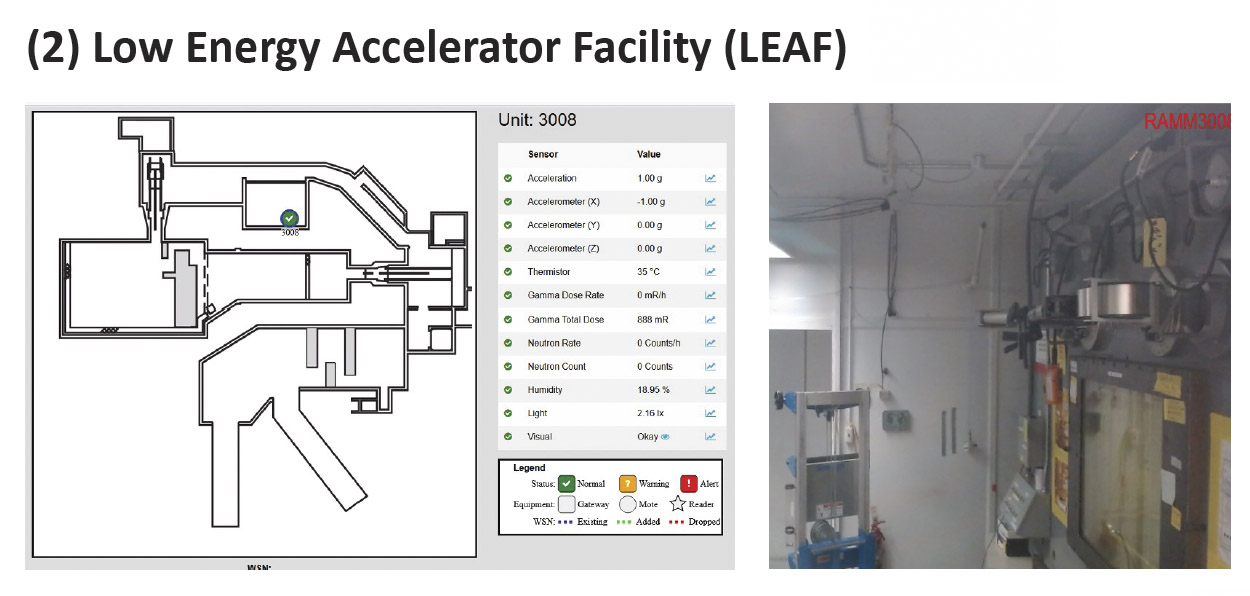

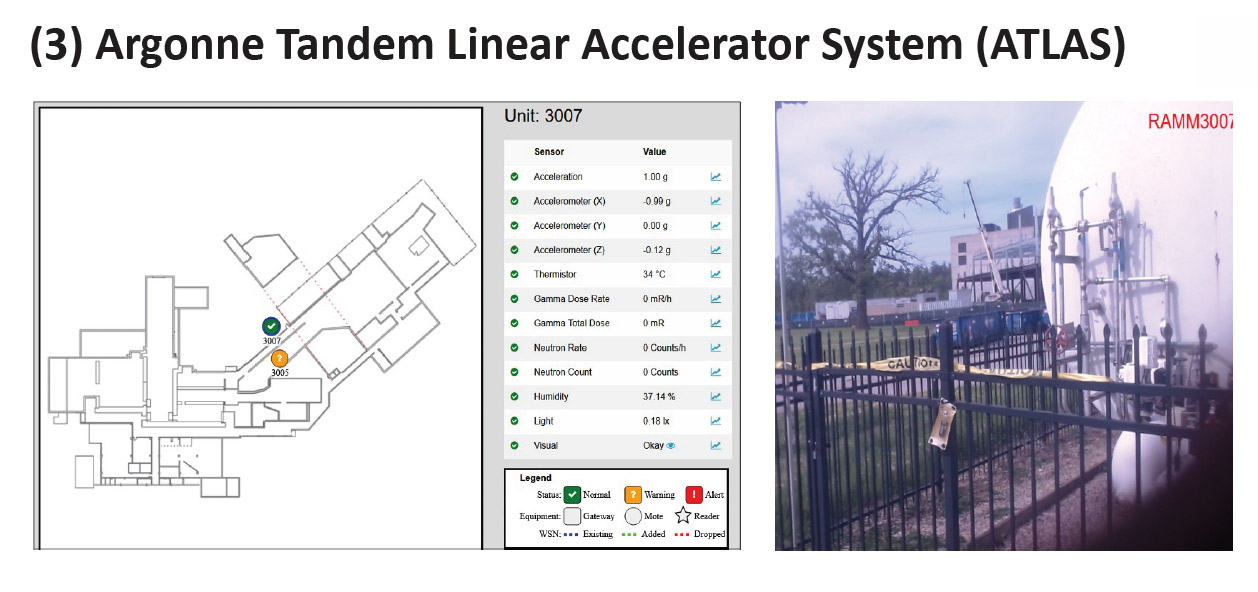

Fig. 2. AGHCF, LEAF, and ATLAS nuclear facilities at Argonne.

At Argonne, the ARG-US RFID and RAMM systems have been installed and operated since 2018 in three nuclear facilities (Fig. 2):

1. The Alpha-Gamma Hot Cell Facility (AGHCF), which is a Category 3 radiological facility undergoing facility decommissioning.

2. The Low Energy Accelerator Facility (LEAF), which produces a wide range of useful radioisotopes for medical, national security, basic science, and industrial applications.

3. The Argonne Tandem Linear Accelerator System (ATLAS), which is a DOE national user facility for high-energy physics.

The continued operation of the ARG-US RFID and RAMM systems in these facilities provides invaluable data on sensor performance and systems reliability in actual operating facilities.

Transportation

Three successful demonstrations of ARG-US technologies include a DOE/Equipos Nucleares S.A. (ENSA) rail/cask shipment of mock spent nuclear fuel (SNF) assemblies, a Westinghouse truck shipment of pressurized water reactor fresh-fuel assembly containers, and a BUP-500 Type B package box truck shipment of thermoelectric generators.

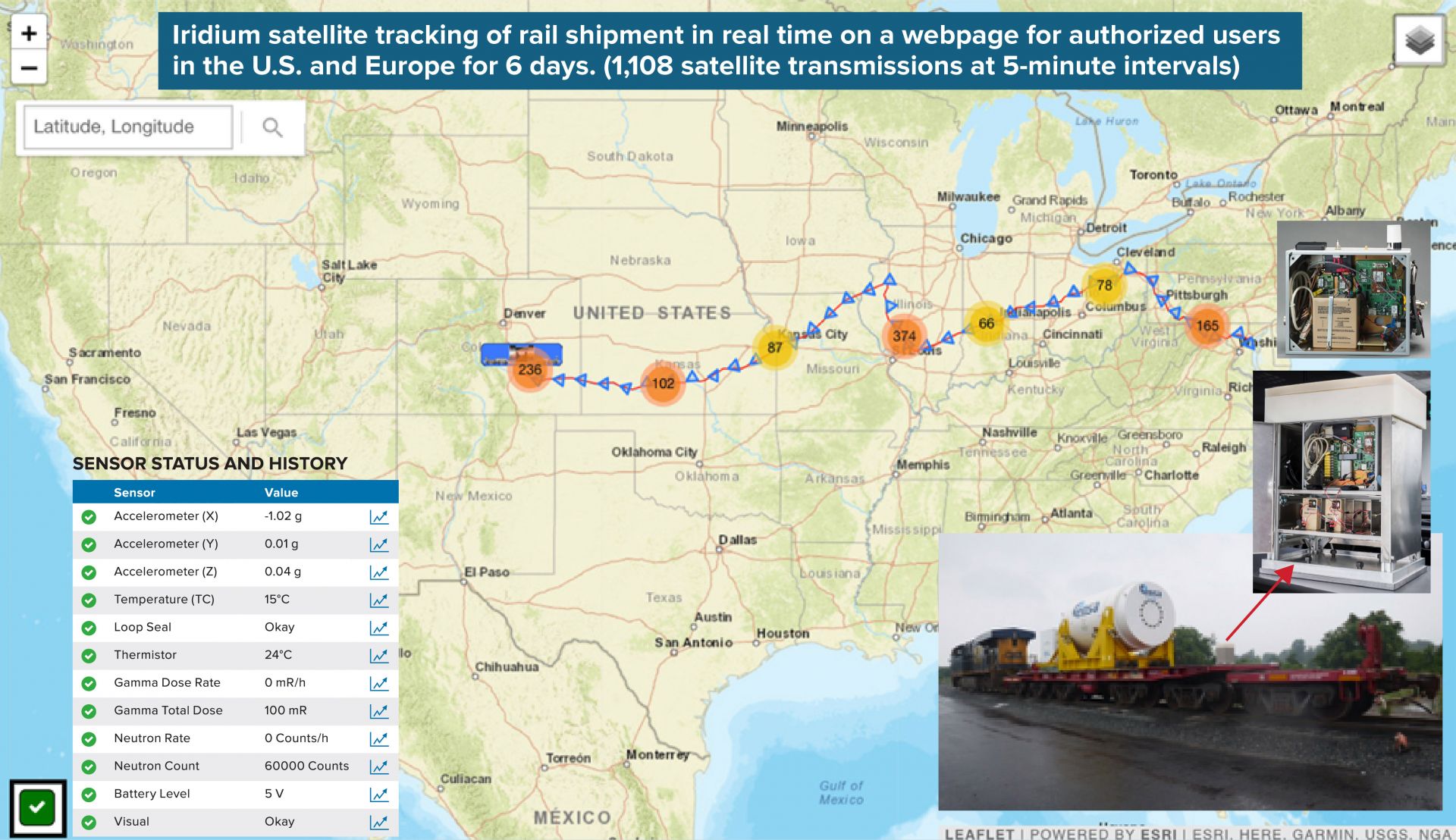

Rail/cask shipment of mock SNF assemblies (July 28–August 3, 2017)

The rail shipment began in Baltimore on July 28, 2017, and the train arrived in Pueblo, Colo., on August 3. The ARG-US TRAVELER tracked and monitored the rail shipment of the DOE/ENSA transport cask for six days without a glitch—a password-controlled, public accessible webpage was made available to authorized personnel so that they could observe the rail shipment of the transport cask in real time.

Fig. 3. Rail/cask shipment of mock SNF assemblies.

The map above (Fig. 3) shows the route of the six-day rail shipment. The aggregated breadcrumbs (indicated by orange and yellow circles on the route shown in the map) show a total of 1,108 satellite transmissions at five-minute intervals. On the webpage, authorized users would expand the clusters of aggregated breadcrumbs and see the geographic locations (latitude and longitude) and time stamps for each breadcrumb and associated sensor values (shown in the insert at the lower left corner of the map), thus tying together the spatial and temporal domains of interest of the entire journey. There were no sensor alarms during the six-day rail shipment, including the time during which the rail carrier was switched from CSX to Burlington Northern near Kansas.

Truck shipment of PWR fresh-fuel assembly containers (May 15–23, 2019)

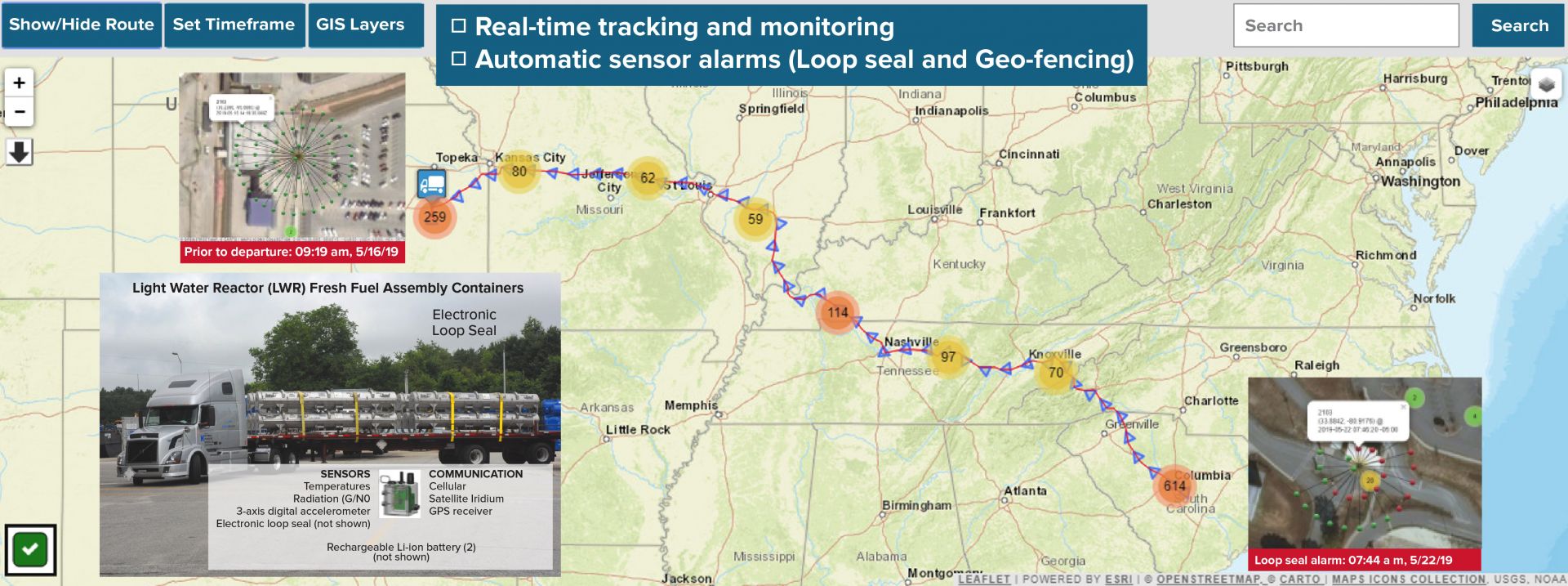

In 2019, Argonne demonstrated the round-trip performance and reliability of the TRAVELER during a truck shipment of PWR fresh fuel assembly containers from Westinghouse’s Columbia Fuel Fabrication Facility (CFFF) in Columbia, S.C., to the Wolf Creek nuclear power plant, in Wolf Creek, Kans., and back.

The Fig. 4 map shows the first half of the shipment. The truck shipment demonstration was supported by funding through a strategic partnership project with Westinghouse Electric Corporation. Geofencing, a server-based program developed for TRAVELER, was fully demonstrated in the Westinghouse shipment, validating its use in transportation planning, operational control, and security for the shipment of nuclear and other radioactive material—including in-transit storage and border crossing.

Fig. 4. Truck shipment of PWR fresh-fuel assembly containers.

Key highlights of the demonstration include:

The cellular GPS receiver in the TRAVELER provided the real-time location of the truck during shipment at one-minute intervals;

A travel log provided breadcrumbs—each marked with geographic location (latitude and longitude) and a time stamp, as in the rail/cask shipment of the mock SNF assemblies; and

The geofence program provided notifications of arrival, as well as violations, such as loop seal alarm (shown in the insert at the lower right corner of the map).

Box truck shipment of BUP-500 radioisotope thermoelectric generator (January 23, 2024)

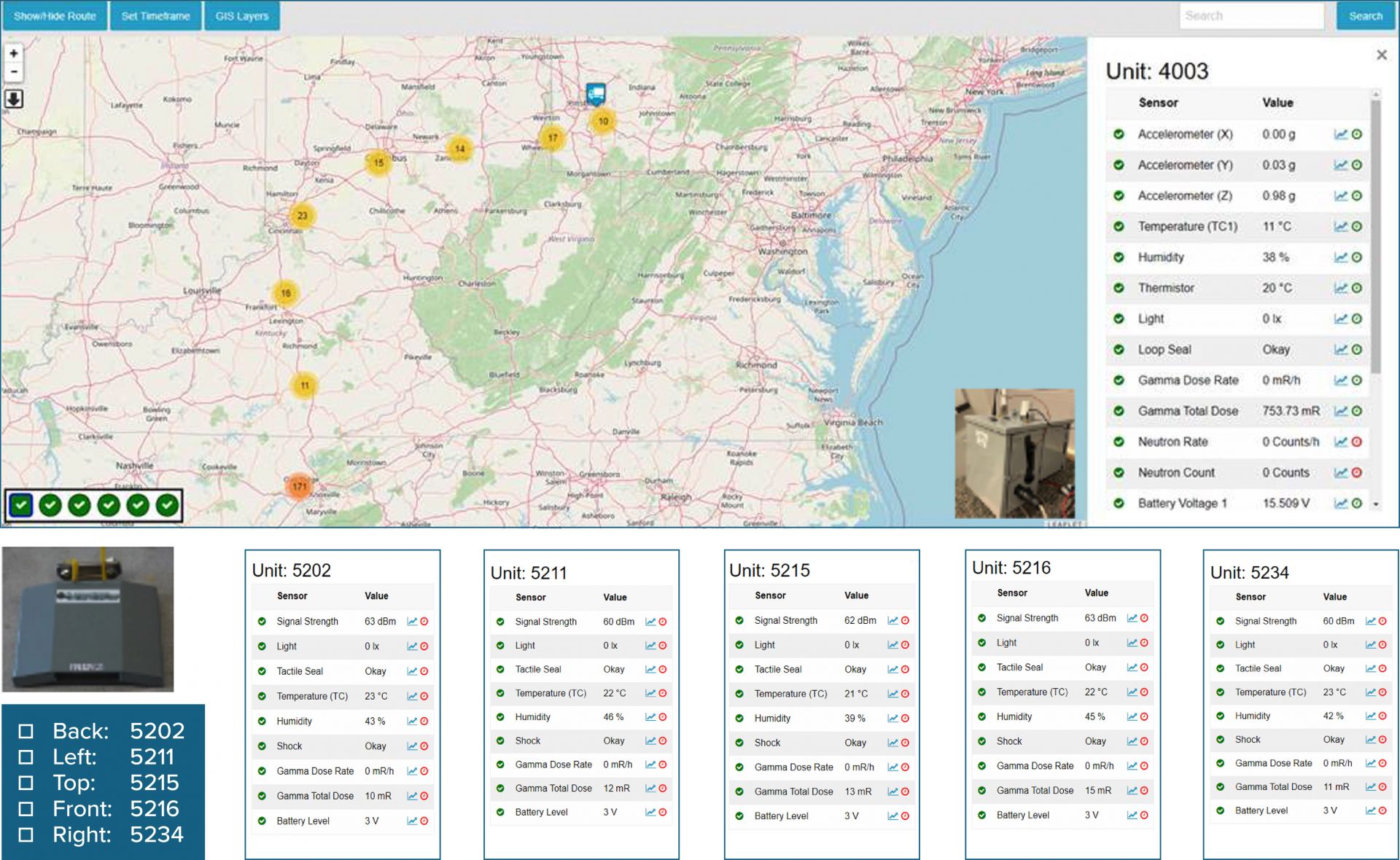

The BUP-500 is a 500-We radioisotope thermoelectric generator (RTG) designed by Teledyne Energy Systems for the DOE in the 1980s. BUP is named after the Byproduct Utilization Program. A prototype BUP-500 was built, but it was not placed into service. In December 2023, the DOE issued an exemption from DOE Order (O) 460.1D, “Hazardous Materials Packaging and Transportation Safety,” for a one-way, one-time shipment of the BUP-500 package from Oak Ridge National Laboratory to the Westinghouse Churchill Site for subsequent removal, recovery, and reutilization of the RTG heat source radioactive material (strontium-90) for defense and space applications (Fig. 5).

The DOE exemption was based on an independent technical review of the application submitted by the Oak Ridge Office of Environmental Management (OREM) and performed by DOE Packaging Certification Program staff, who reviewed the exemption application and supporting documentation, including the BUP-500 transportation plan prepared by United Cleanup Oak Ridge LLC (UCOR) in accordance with the DOE Order 460.2B, Departmental Materials Transportation Management. The plan includes tracking the shipment by using ARG-US RFID tags and driver inspections. The operational controls specified the use of five ARG-US RFID tags attached to the BUP-500 package and a reader (TRAVELER) inside the box truck to remotely track the shipment and monitor package temperature, radiation, and shock in real time.

Fig. 5a. RFID tags on off-loaded BUP-500 package.

Figure 5a shows the RFID tags on the off-loaded BUP-500 package after arriving at the Westinghouse Churchill Site on January 24, 2024. Figure 5b, below, shows the 11-hour history of the shipment (cellular GPS at one-minute intervals) and sensor data of five RFID tags and the reader (Unit 4003) recorded at 8:12 a.m. EST on January 24, 2024.

Following the completion of the BUP-500 shipment, DOE/OREM issued a press release on January 26, 2024, that included a group photo showing a celebration of partnership among leaders of UCOR, DOE-EM, OREM, Zeno Power, and NASA in reusing legacy radioactive material previously stored at Oak Ridge for future power sources. In the following days, the Knoxville News Sentinel, SpaceNews, and GeekWire published articles on the BUP-500 shipment and Zeno Power’s radioisotope system for space and underwater applications.

Fig. 5b: The history of box truck shipment of BUP-500 radioisotope thermoelectric generator.

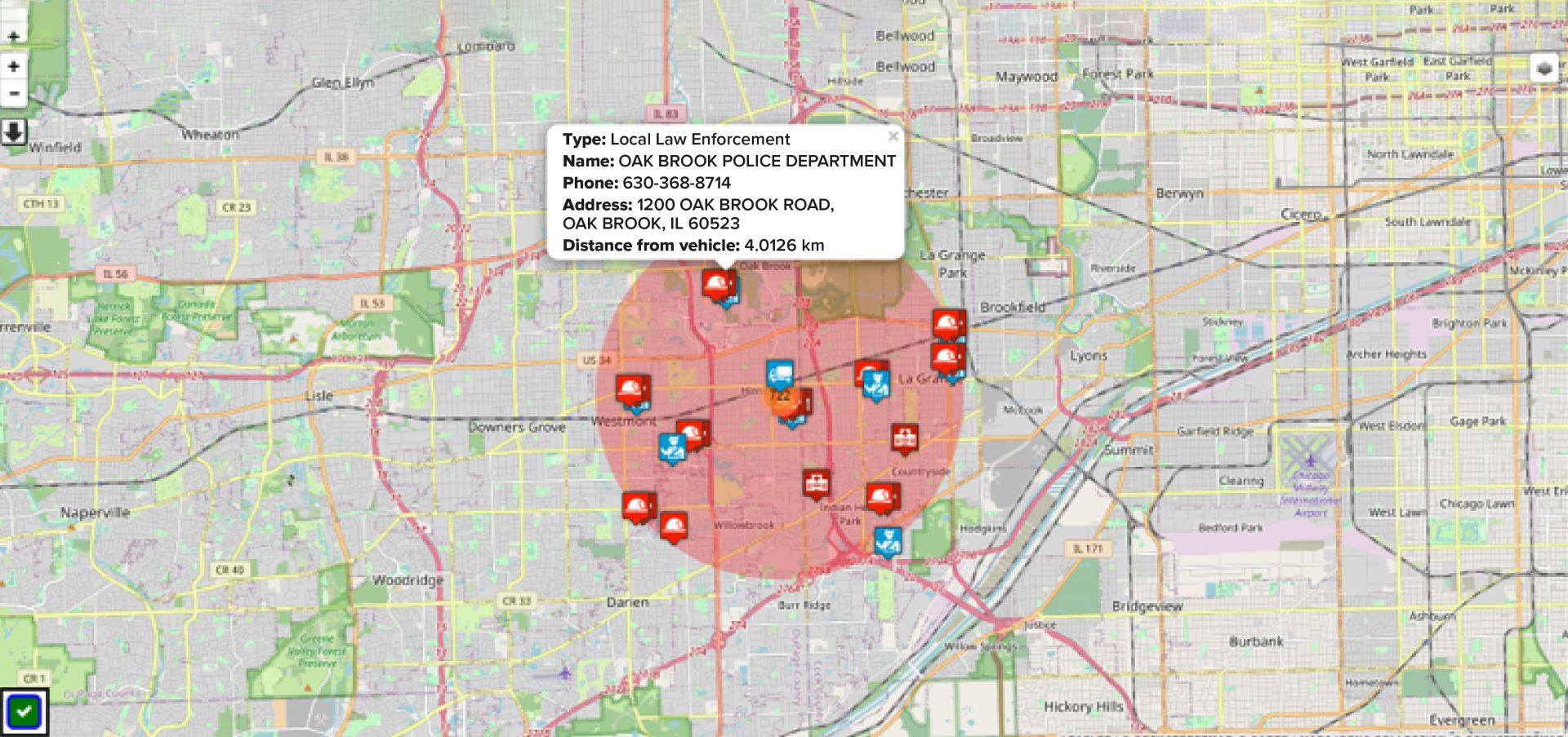

Geofencing (GF) and geographic information system (GIS)

GF and GIS are two server-based programs developed for the ARG-US remote monitoring systems for real-time transport security and transport emergency response applications. The Fig. 6 map below shows the resources (e.g., hospitals and local law enforcement and their contact information) located within the zone defined by the radial distance from the vehicle’s incident location.

Fig. 6. Resources located within the zone defined by the radial distance from a vehicle’s incident location as displayed in the GIS.

The ability to monitor critical parameters in nuclear facilities and transportation during normal operation—and, significantly, during and after a disruptive incident and/or accident—is vital for the safety of facility personnel, emergency responders, recovery crews, and residents of the surrounding communities. Conventional hard-wired assets that depend on supplied power may be decimated by natural disasters or by the malicious acts of attackers, either physical or cyber. The ARG-US remote monitoring systems are designed with multiple power supplies, including rechargeable lithium-ion batteries that can operate for at least 72 hours after a disruptive incident or accident.

As additional context for the value and impact of the ARG-US technology, using surveillance and automatic sensor alarms for remote monitoring of nuclear facilities 24 hours a day, 7 days a week (24/7) is analogous to the use of home security systems. These systems help ensure that family and property are always protected, because they enable appropriate emergency response teams to immediately address incidents and accidents. Similarly, real-time remote monitoring of packages of nuclear and other radioactive material using ARG-US during transportation not only ensures 3S but also emergency response and consequence mitigation.

Looking ahead

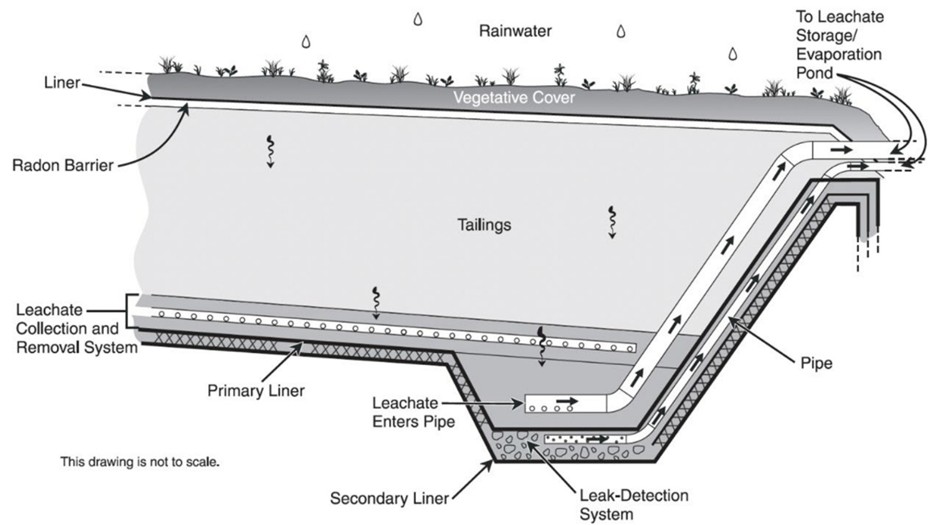

The open literature often illustrates the nuclear fuel cycle with clockwise movements of nuclear materials between fuel cycle facilities (e.g., conversion, enrichment, fuel fabrication, power plant, pool and dry storage, reprocessing, and disposal). Each step in the cycle can vary in duration from years to decades, and the overall cycle may last over centuries when fuel cycle materials are in final disposal.

Given the complexity and duration of the nuclear fuel cycle, the packaging of materials in various physical and chemical forms must be designed and manufactured to meet the safety requirements of containment of radioactivity; protection against radiation; and criticality control during transportation, storage, and disposal. No structures, systems, and components of a nuclear packaging can maintain their safety functions without the management of aging-related environmental degradation of materials over time.

The individual objectives of nuclear packaging in operation are to (1) protect people from radiation (safety), (2) protect materials and facilities from malevolent people (security), and (3) protect society from nuclear weapon proliferation (safeguards). The common objective of nuclear packaging in operation, combining the three individual objectives of 3S, can be stated as, “Protect people, society, the environment, and future generations from the harmful effects of ionizing radiation.”

Argonne researchers and the DOE have established a framework for “3S by design” by drawing on the accumulated knowledge in packaging for the transportation of nuclear and other radioactive material and extended long-term storage of SNF and high-level radioactive waste, including aging management, as well as the ARG-US remote monitoring systems technologies. This framework should be applicable to meeting the challenge of packaging 3S for existing and advanced nuclear fuel cycle materials in the transportation, storage, and disposal phases. n

Yung Liu is a senior nuclear engineer who leads the Packaging Certification and Life Cycle Management activities in Argonne’s Decision and Infrastructure Sciences Division (www.anl.gov/profile/yung-y-liu). Kevin A. Brown coordinates communication services and leads project teams as part of Argonne’s Writing Center of Excellence, Communications and Public Affairs Division.

Training the next generation of packaging professionals

Argonne recognizes that inspiring and educating a future generation of nuclear packaging professionals who will drive “3S by design,” and the packaging industry more broadly, is not just a challenge, but an opportunity. Argonne and the DOE Office of Environmental Management’s Office of Packaging and Transportation, through the Packaging Certification Program, have been proactive in leveraging unique resources and expertise across the DOE laboratory system to pursue this opportunity.

In summer 2025, Argonne will launch a Packaging University Summer Institute, sponsored by the DOE Packaging Certification Program. Argonne’s proven and comprehensive expertise in packaging technology development and implementation, experience and resources in educational outreach, and expertise in communication and program strategy are being leveraged to launch the institute, which will enhance the STEM (science, technology, engineering, and mathematics) education portfolio at Argonne.

The Packaging University Summer Institute supports the mission of DOE-EM’s Office of Packaging and Transportation to bridge the knowledge and experience gap between longtime experts in nuclear packaging and college and university students, as well as early- and mid-career professionals looking for opportunities to enter the field. The summer institute also enhances Argonne’s support of the DOE-EM Packaging University Program. For the nuclear industry, the institute will help industry and regulators identify, recruit, train, retain, and advance motivated employees, as well as gain credibility with clients.

Argonne’s vision and investment in advanced technology development, application, and education, with the ongoing support of DOE-EM’s Office of Packaging and Transportation, continues to help ensure 3S by design and the support of key stakeholders, both domestic and international.

To learn more, please visit the web sites below: