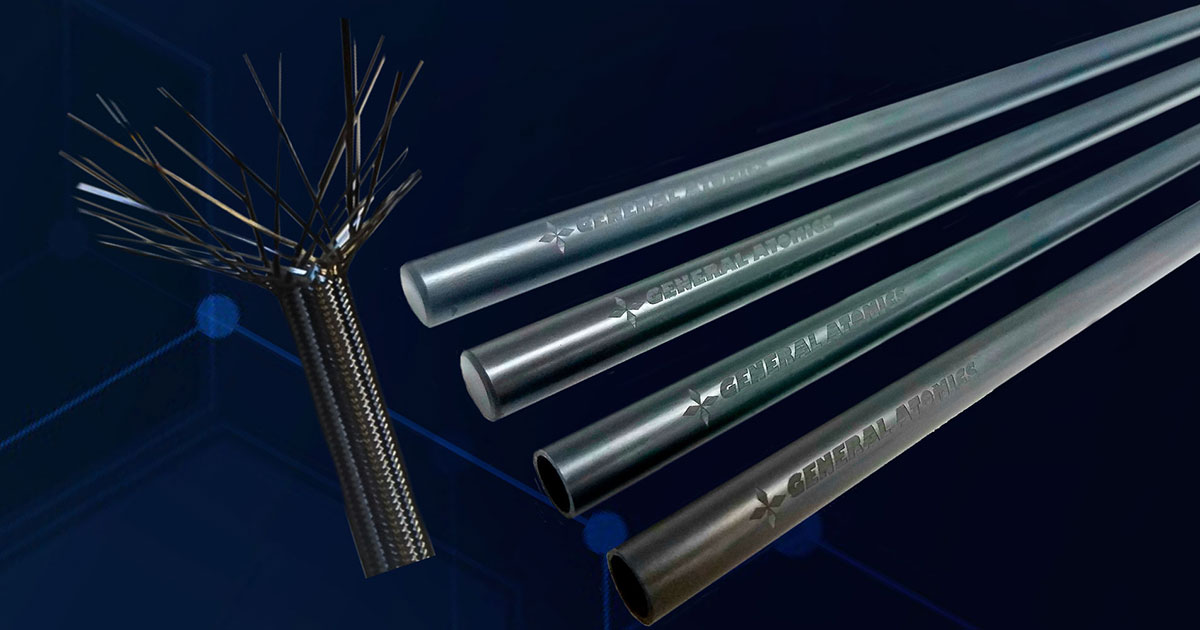

General Atomics’ SiGA-cladded test rods complete irradiation testing in the ATR

General Atomics Electromagnetic Systems (GA-EMS) announced last week that unfueled test rods featuring the company’s SiGA fuel cladding—made of a silicon carbide composite material—successfully survived 120 days of irradiation in the Advanced Test Reactor (ATR) at Idaho National Laboratory.