GammaTrend Monitoring of Reactor Coolant using Pixelated CZT Spectrometers

Real-time source-term monitoring supports decisions and investments

H3D, Inc.’s GammaTrend technology collects and displays continuous, real-time data showing the dynamics of the radiological source term in plant systems. GammaTrend provides minute-by-minute results, allowing for an improved understanding of how specific plant operations and water-chemistry changes impact radionuclide transport.

Plants using GammaTrend have reported significant results, including reductions in outage dose rates and critical-path time. Some plants have identified previously unknown (or poorly characterized) impacts resulting from insoluble radionuclides such as silver-110m (Ag-110m) deposited within pipes and not collected in water-chemistry samples. Because GammaTrend is deployed in the field, the presence of radionuclides deposited in the pipe and contributing to local dose rates is also captured by the measurement.

The detectors used in GammaTrend are based on pixelated cadmium-zinc-telluride (CZT) technology, which allows for high-resolution gamma spectroscopy without the need for liquid nitrogen or mechanical cooling. This makes CZT the perfect choice for field-deployable, long-term, and real-time gamma spectroscopy.

These detectors provide a powerful tool to monitor impacts to plant source term from physical and chemical changes to plant systems, such as reactor coolant temperature, pressure, pH, and chemical additions.

GammaTrend monitoring supplements traditionally available water chemistry and radiation dose-rate measurements. The availability of real-time radionuclide trending provides insights about the current state of the radiological source term to support tactical decisions such as when to cease a forced oxidation cleanup or open access to restricted areas.

Deployment of GammaTrend technology has provided significant learnings to support the development of strategic source-term reduction initiatives. The large volume of data collected and the ability to more confidently correlate plant operations to changes in radiological distributions provides a powerful new source of information to consider when making significant investment decisions towards improving the radiological conditions for the workers. Data monitoring following the implementation of dose-reduction initiatives provides validation of impact.

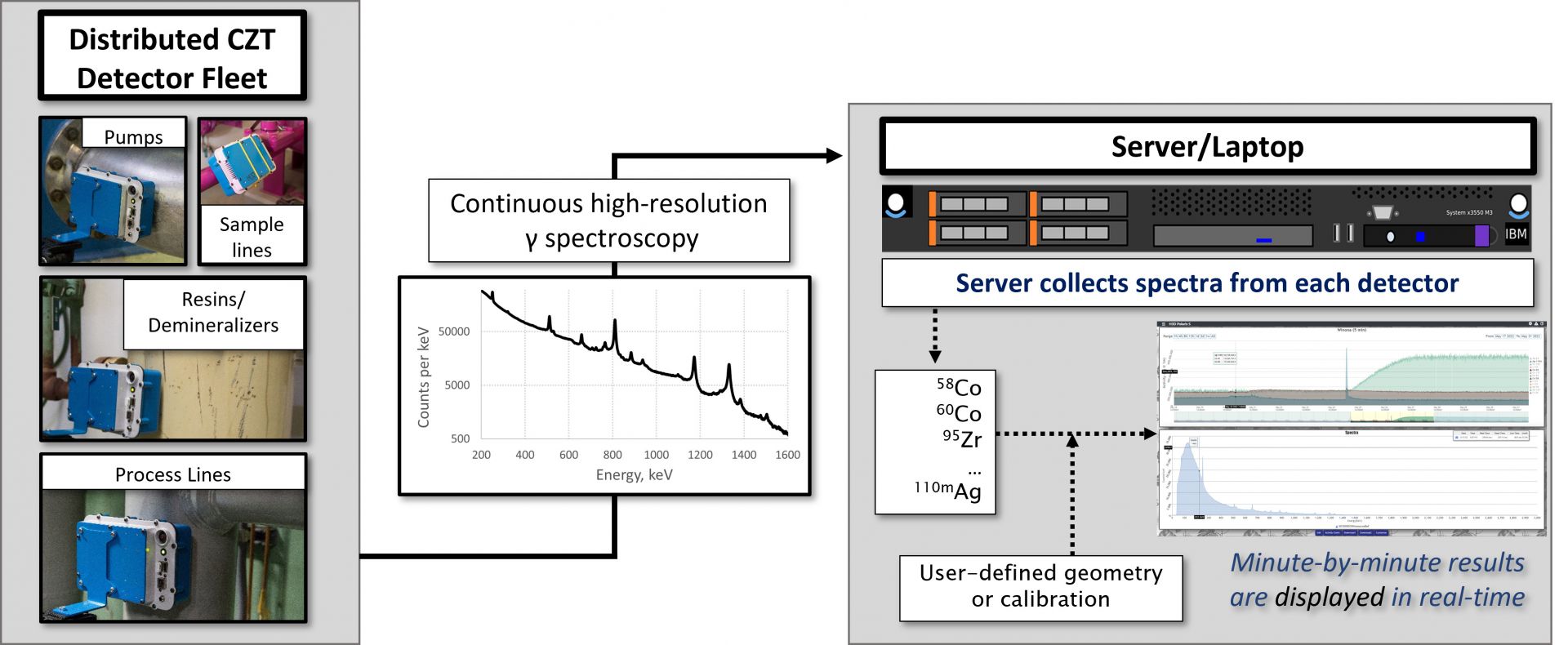

GammaTrend system description

Figure 1 - Representation of a GammaTrend system. Field detectors transmit data over ethernet or radio to a laptop or LAN server.

A typical GammaTrend system is depicted in Figure 1. A system consists of one or more H3D, Inc. S100-model gamma spectrometer(s). P100S shielded spectrometers can also be used for higher dose-rate environments or where a collimated detector is needed due to the presence of other non-relevant radiation sources in the area. The S100/P100S units plug into a local power outlet and are designed to run continuously for an operating cycle (often more) without intervention.

The detectors collect, process, and communicate new radiation spectra each minute. These spectra are communicated via ethernet or radio transmitter to a server operating the GammaTrend web-based software suite. The software provides tools to monitor system/detector health and to provide remote control functions to start/stop measurements (and other features) without having to enter the radiologically controlled area.

GammaTrend software provides for long-term collection and display of the data received from each connected detector. Standard displays are available to provide qualitative trending of radionuclide-specific count rate or as an indication of the percent-of-dose-rate resulting from each individual nuclide. The measurement geometry (e.g., pipe size and materials, distance, etc.) can even be modeled to provide a real-time estimate of radionuclide concentration in the process line.

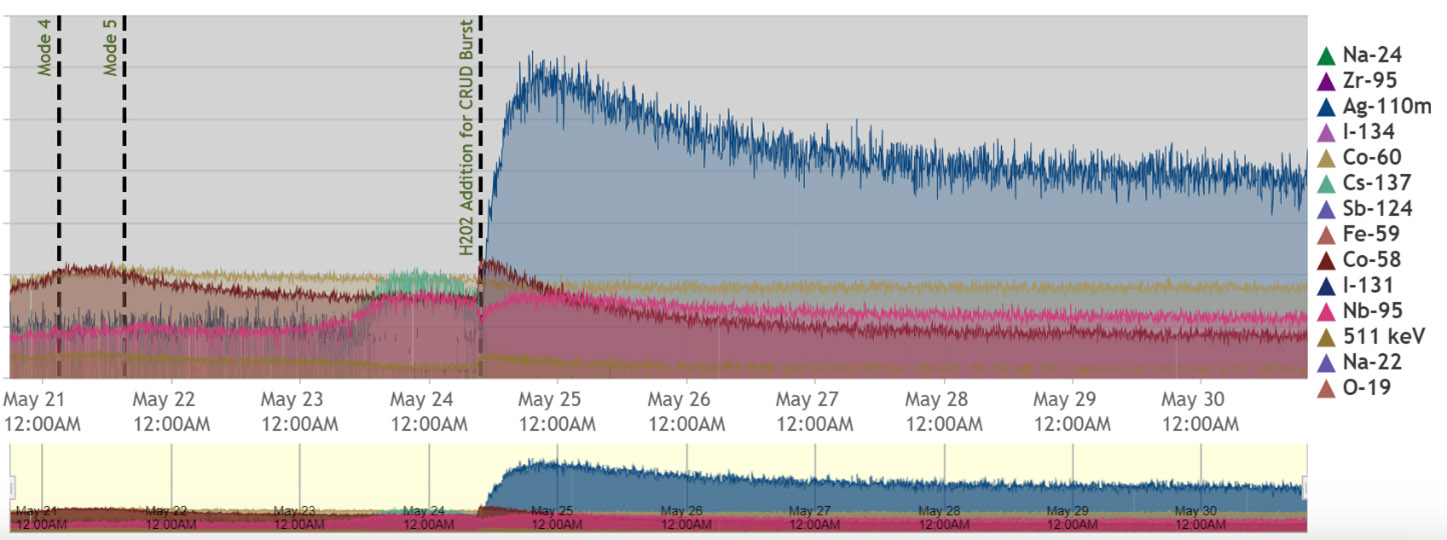

Outage and CRUD-burst monitoring

GammaTrend was initially developed based on the feedback of radiation protection managers who saw the potential to improve the monitoring of radiological source term during the forced oxidation “CRUD burst” in pressurized water reactors.

With the trending precision offered by minute-by-minute results, GammaTrend allows the user to monitor the cleanup curve more precisely and quickly, allowing for the earlier identification of cleanup occurring slower than expected. The sheer volume of data points provides additional confidence in predicting and validating the progress of the cleanup. Decisions on when to cease the cleanup and/or provide access to areas restricted during the cleanup are supported by a large amount of data that are being continuously collected.

Figure 2 - Typical forced-oxidation "CRUD burst" cleanup curve

Figure 2 shows the typical early outage trending (including the forced oxidation period) at a PWR. The measurement provides radionuclide-specific results, enabling a better understanding of how the physical and chemical changes impact each during the transition into an outage.

Comparison of the results before and after the cleanup period allow for an assessment of the expected radiological conditions resulting from the evolution. Comparisons of data collected during consecutive outages, or examination of data from two separate reactor units, can provide key insights into the impact of multiple parameters on results.

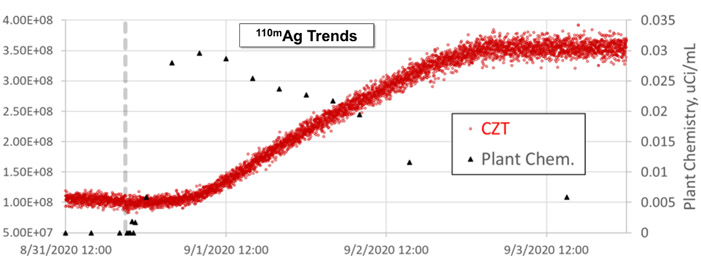

Silver-110m and other insoluble species

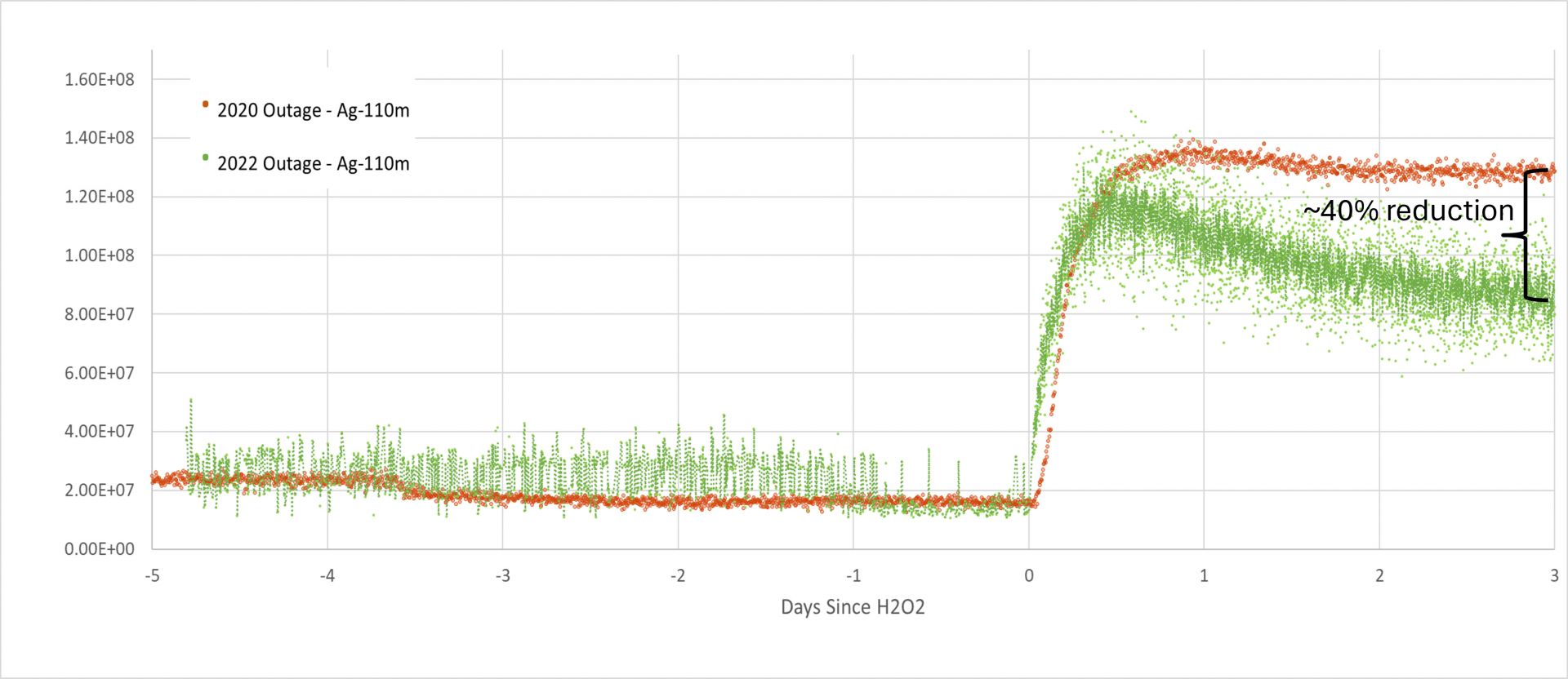

Figure 3 - Silver-110m trends following forced oxidation. GammaTrend measurements effectively monitor an increasing trend due to insoluble silver depositing in the process line.

Several plants use GammaTrend to provide essential monitoring of the impacts of Ag-110m in their systems. Silver’s complex chemistry yields insoluble species at lower system temperatures present in reactor coolant purification loops downstream of heat exchangers, making it difficult to monitor using traditional water chemistry sampling techniques. Figure 3 shows data highlighting the limitation of water sampling at characterizing insoluble species like silver – as it collects in the line that is being monitored, it is no longer available to be collected in the water sample. Because GammaTrend monitoring is performed local to process lines, insoluble species like Ag-110m are captured by the detectors.

Unfortunately, Ag-110m is a hard gamma-emitter that can contribute a significant fraction of the dose rate in these areas of the plant – an impact that has not always been well understood due to the limitation of traditional monitoring. GammaTrend monitoring of Ag-110m has been a critical contributor to plant-specific and industry discussions seeking to mitigate the impacts of silver contamination in the plants.

Supplemental fuel-defect monitoring

Recently, this technology has been used at multiple facilities to precisely trend xenon concentrations resulting from small fuel defects during operating cycles. The same detectors used during the outage period were left in place during the subsequent operating cycle.

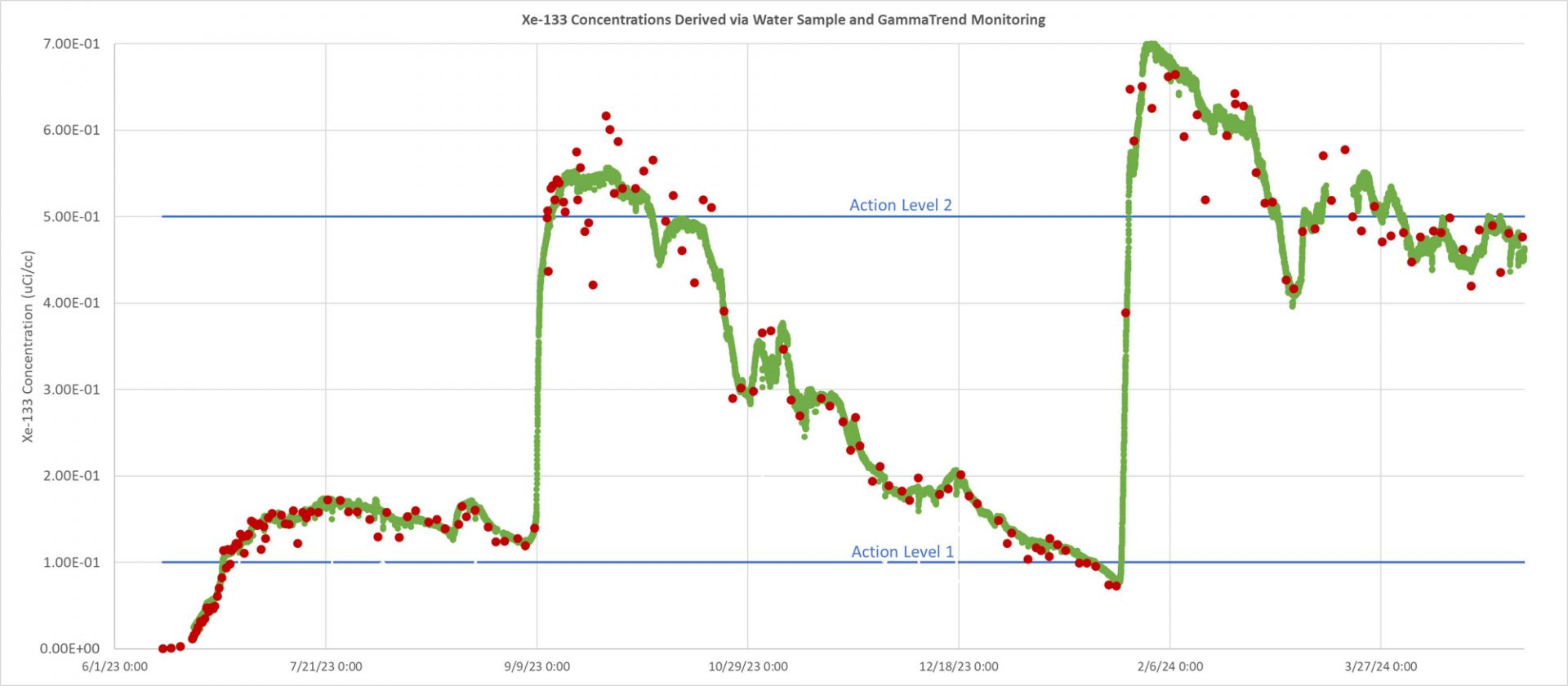

Figure 4 - Overlay of GammaTrend and water chemistry results monitoring Xe-133 from a fuel defect.

These examples have demonstrated that GammaTrend can be effectively used to continuously measure Xe-133 and Xe-135. While water chemistry results are needed to fully characterize small defects (e.g., iodines in small concentrations and difficult-to-detect radionuclides), these plants have found that continuous monitoring of xenon can be an effective supplemental monitoring tool to ensure that changes in the defect condition are identified quickly to prompt sampling.

Figure 4 shows good agreement between Xe-133 results obtained using GammaTrend and water sampling. The volume and immediacy of data available from GammaTrend makes step changes in the condition very apparent, allowing for notifications of personnel, prompting of additional sampling, and, if relevant, investigation of plant operations that occurred at the time of the change.

Strategic source-term reduction

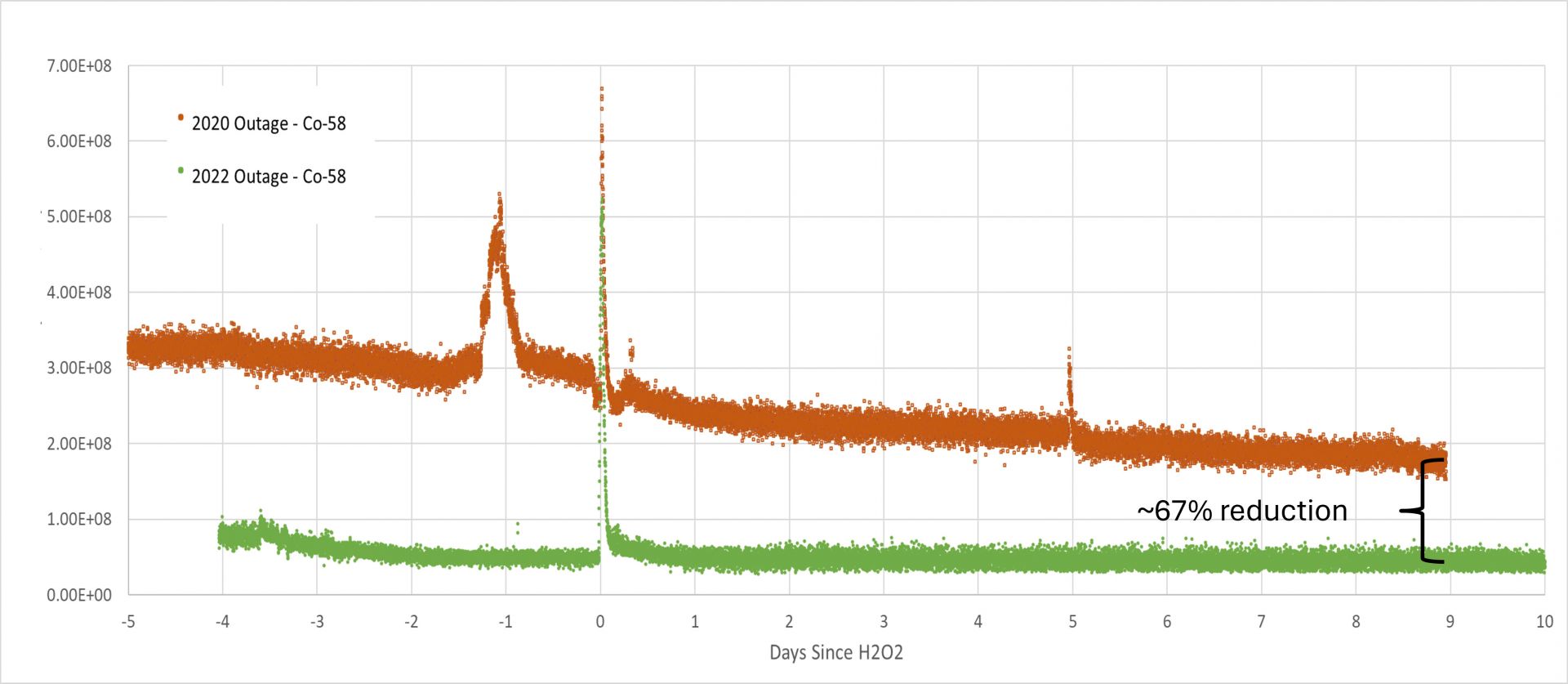

Figure 5 - Outage-to-outage comparison showing the improvement in Co-58 (top) and Ag-110m (bottom) following the implementation of revised operating cycle and shutdown chemistry scheme.

Strategic dose-reduction plans (e.g., “Five-Year ALARA Plan”) traditionally detail the historical dose performance for a unit/station and commit to initiatives intended to continue reducing worker exposure. Stations using GammaTrend are finding that the data collected by these systems are very relevant to these discussions and can provide effective inputs into identifying the correct initiatives to yield the intended results. GammaTrend also allows for better verification that the intended results were achieved.

For instance, one plant used GammaTrend data collected during a previous cycle to benchmark industry leaders on plant-shutdown strategies. Improvements were identified to improve source term cleanup during the initial outage shutdown sequence and, more specifically, improve the delivery of silver to the purification demineralizer for cleanup. Multiple changes in coolant temperature, pH, end-of-cycle boron concentration, and improved acid-reducing conditions were made during the following outage shutdown. Some of the results are shown in Figure 5. GammaTrend data provide clear evidence validating the impact of the changes made, showing significant reductions in both the Co-58 and Ag-110m inventories during the subsequent outage.

Expected and unexpected Changes

While most users implement GammaTrend to monitor expected changes, such as CRUD bursts, many find benefits in the ability to identify unexpected trends and changes. Leaving the detectors in place for long periods of time allows for better understanding of those things that impact source term.

Powerful benchmarking data

GammaTrend provides a lot of data – data that can be readily used to compare outages, operating cycles, reactor units, and to prompt benchmarking conversations on source-term impacts and potential improvements.

For more information on GammaTrend monitoring or any of H3D’s innovative gamma spectrometer devices, visit www.h3dgamma.com or send us a message at sales@h3dgamma.com.