An alpha recoil: Researchers at Yale manufactured silica spheres just 3 microns wide implanted with radioactive lead-212 atoms for an experiment that could have implications for the search for dark matter and nuclear forensics. Referencing none other than Dr. Seuss, Physics magazine told the story in graphic novel style with the headline “Sensing a Nuclear Kick on a Speck of Dust.”

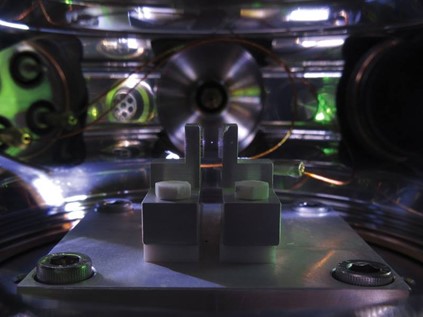

Dr. Seuss aside, the research in the lab of Dr. David Moore at Yale was supported through the Quantum Horizons: QIS Research and Innovation for Nuclear Science program of the Department of Energy’s Office of Science and published in July in Physical Review Letters. In a September 4 release, the DOE explained that the silica microparticles were trapped in a high vacuum at pressures of less than 10-10 atmospheres. Using an “optical tweezer” or “optical trapping” technique—a laser focused on the center of the vacuum confined the microparticle to a small region where it rotates with gyroscopic stability as the Pb-212 slowly decays.

The researchers used the light scattered by the microparticle to track its position and look for any small jumps in the microparticle’s motion that could arise from nuclear decays. They were able to detect alpha particle emissions by noting a change in the electric charge and a simultaneous “tiny recoil” of the microparticle. Despite the microparticle being more than a trillion times heavier than the alpha particle emitted, movement of about 10 nanometers was detected.

By using smaller nanoparticle spheres and quantum sensing to measure the particle’s position and momentum, more precise measurements could make it possible to detect the kick from a single beta, gamma, or neutrino emission using the same technique, according to the DOE.

“Clean energy” takes on new meaning: Dust in fusion tokamaks might sound routine—dust particles are generated by plasma-wall interactions in an operating machine, degrading its surface and sending tiny solid particles of the material into the plasma, and that phenomena is studied carefully. But the dust ITER is contending with, years before operation, is something else entirely.

In a news article titled “Vacuum and cleanliness: Space solutions for terrestrial dust,” published on September 9, the ITER Organization describes how the its vacuum team “realized that the level of construction debris and concrete dust in the Tokamak Building meant key components were getting so dirty that the machine might never operate to specification” and how cleanliness techniques developed for satellite engineering are now protecting ITER from contamination.

The vacuum team knew that construction activities posed a risk of contamination, but wasn’t aware of the extent of the problem until a mandatory cleanliness report was ordered after vacuum vessel sector 6 was brought to the assembly pit in 2022. That report showed concrete dust contamination on pit surfaces and “an abundance of metallic particles from milling known as ‘swarf.’”

“We had traditional cleaning methods such as chemical wiping, but as assembly progresses, the complexity of the system means there will be areas we can't physically get to,” said Liam Worth, the vacuum systems project leader. “We needed a technical and philosophical change to get people to understand that it was essential to establish the cleanliness from the start because it will be impossible to clean later.”

ITER turned to OHB, a German systems integration company specializing in the assembly and operation of satellites for customers including the European Space Agency. The company created an internal Cleanliness Competence Centre and has since shared its approach with external clients.

The senior expert for contamination control at OHB, Axel Müller, identifies as a fusion enthusiast and studied plasma physics at the Technical University of Munich. According to ITER, he was able to apply techniques learned for satellite projects to ITER. Both projects involve assembling components made by different contractors, maintaining cleanliness over time, and ensuring that a device will work smoothly once it is powered up and inaccessible.

Late in 2022, OHB and ITER started a three-phase “cleanliness recovery project.” First, OHB evaluated an approach to the in situ cleaning of vessel sector modules already installed in the pit. The second phase included plans for prototypes of cleaning tools and protective textile covers custom designed for ITER components. The third phase, underway now, involves developing a “cleanliness compliance contract” for contractors and ITER personnel to follow at each construction milestone.

.svg.png)