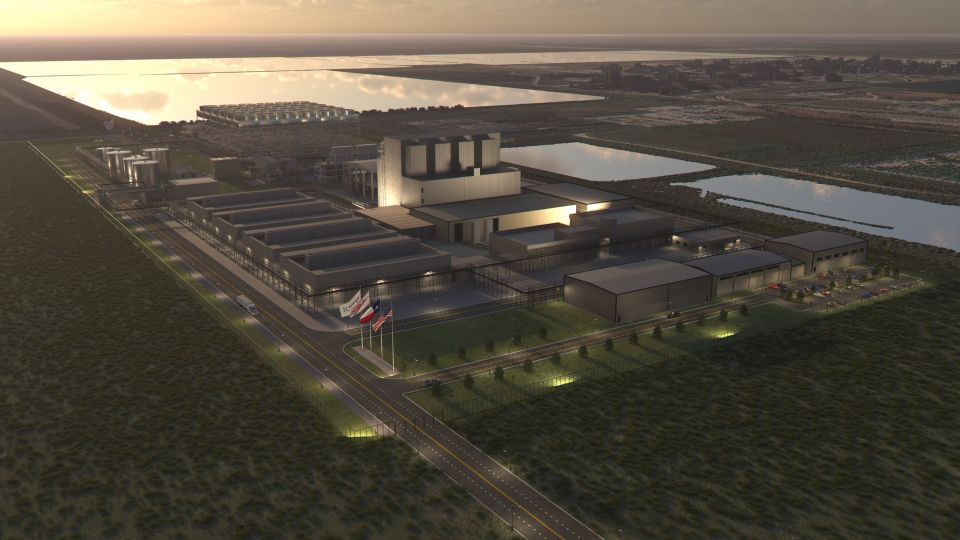

Custom equipment lets ORNL scale up molten salt investigations

Transparency is one advantage of certain molten salts that could serve as both a coolant and fuel carrier in an advanced reactor. For scientists studying molten salt chemistry and behavior at the laboratory scale, it helps if the test vessel is transparent too. Now, Oak Ridge National Laboratory has created a custom glass test cell with a 1-liter capacity to observe how gases move within a column of molten salt, the Department of Energy announced August 5.

-3 2x1.jpg)