Startup heaters installed in Hanford’s second waste melter

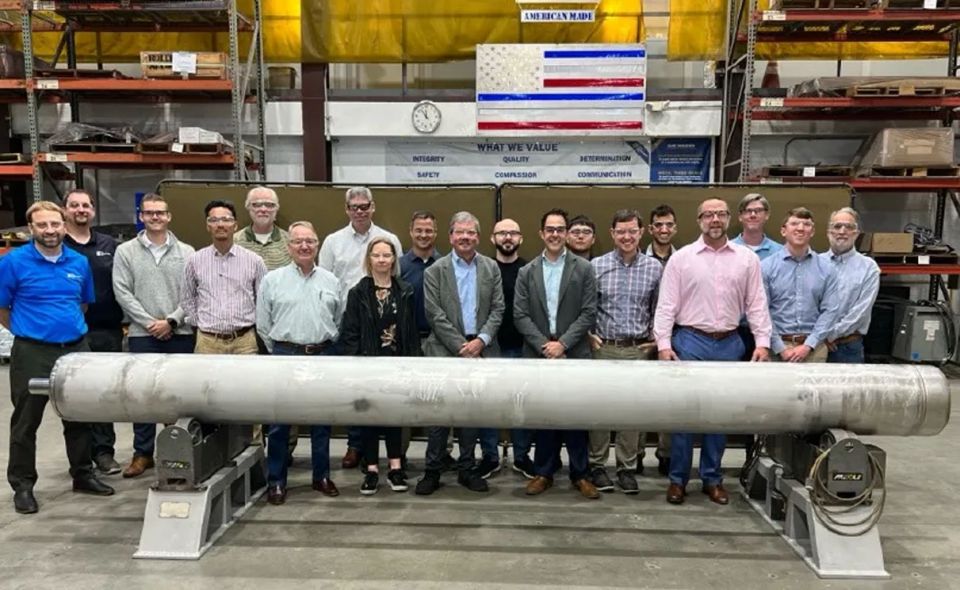

The Department of Energy’s Office of Environmental Management announced that crews at the Hanford Site’s Waste Treatment and Immobilization Plant, also known as the Vit Plant, recently installed 18 temporary startup heaters in the second of two melters in the plant’s Low-Activity Waste Facility.