First container of test glass filled at Hanford’s Vit Plant

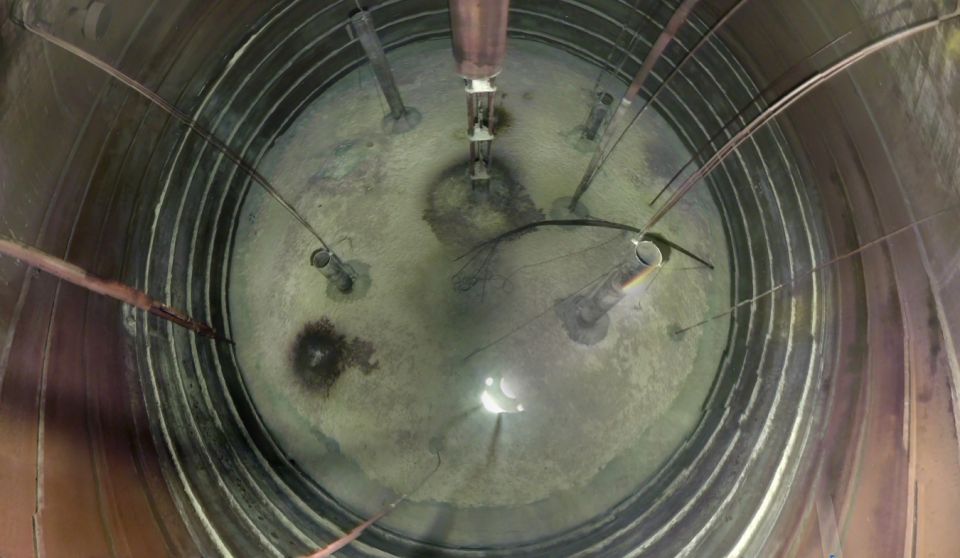

Bechtel and the Department of Energy’s Office of Environmental Management announced on December 4 that the first set of test glass was successfully poured into a stainless-steel storage container designed to hold vitrified waste at Hanford’s Waste Treatment and Immobilization Plant, also known as the Vit Plant.

-3 2x1.jpg)