Root cause of Vogtle and VC Summer delays

This column was initially published in the October 16, 2014, issue of Fuel Cycle Week and is republished here with permission.

Within a few months of receiving its combined operating license in February 2012 the Vogtle-3 & -4 nuclear power plant project became the subject of reports that it was significantly behind schedule and over budget.

Radio station WABE, Atlanta's NPR affiliate station, is closely tracking the project and its publicly released reports. WABE has compiled its story segments into a useful print and audio chronology. There are similar stories about the closely aligned Summer-2 & -3 project.

On September 24, I had the opportunity to tour the Vogtle site and learn first-hand how the project is faring. The wrong people are getting blamed. The resulting misperceptions about the projects have the potential to contribute to another lengthy hiatus in nuclear power plant construction in the United States.

The most important thing I learned during my Vogtle visit was that the construction project is moving as rapidly as predicted, that the people on site and in supporting roles are doing a good job, that the workforce hiring challenges are within the predicted boundaries, and that the regulators overseeing the project are performing as expected.

As is demonstrated by the progress being made on the second units at each site, lessons-learned programs are robust and effective.

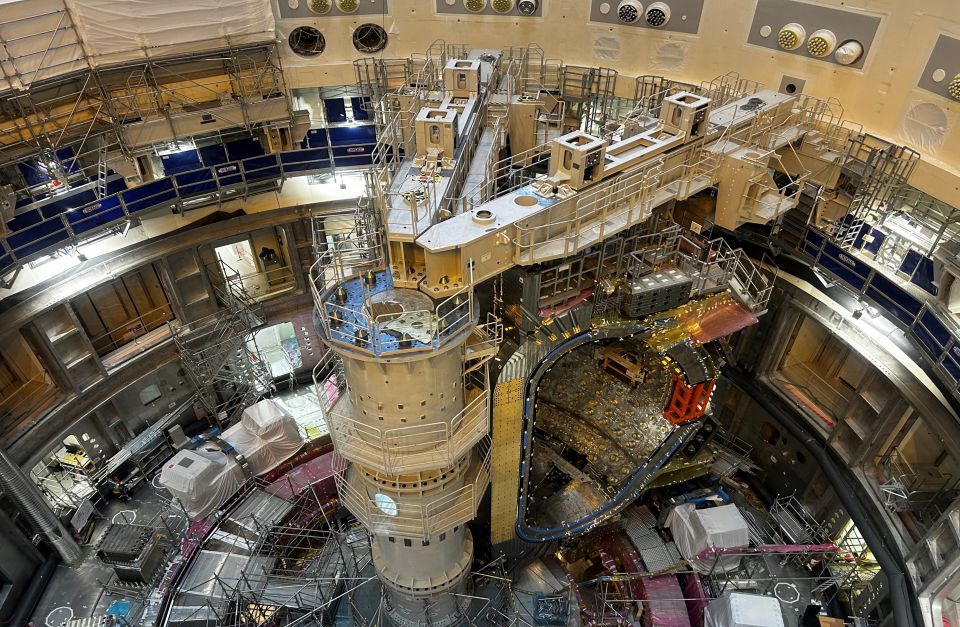

I also saw a growing inventory of large components that was being stored in an expanding number of temporary structures designed to protect the components from the Georgia red clay and frequently inclement weather.

The second most important thing I learned was that the cost increase and ultimate schedule delay could and should have been predicted on the day that amendment 19 of the AP1000 design certification document was approved in December 2011.

The schedulers could have restarted a clock that should have been put on pause when the U.S. Nuclear Regulatory Commission changed the rules two-and-a-half years earlier with the Aircraft Impact Assessment rule.

Regulatory delays cost time and money

The 36-page Federal Register notice issued in July 2009 acknowledged that the Aircraft Impact Assessment rule was not necessary to provide "adequate protection" and it acknowledged that applying the rule to a project that was already under construction would impose an undue financial burden:

"In making these additions, the NRC is making it clear that the requirements are not meant to apply to current or future operating license applications for which construction permits were issued before the effective date of this final rule. This is because existing construction permits are likely to involve designs which are essentially complete and may involve sites where construction has already taken place. Applying the final rule to operating license applications for which there are existing construction permits could result in an unwarranted financial burden to change a design for a plant that is partially constructed. Such a financial burden is not justifiable in light of the fact that the NRC considers the events to which the aircraft impact rule is directed to be beyond-design-basis events and compliance with the rule is not needed for adequate protection to public health and safety or common defense and security."

What that concession did not admit was the enormous financial and schedule impact of applying the rule to two existing projects for which designs were already certified, firm EPC (engineering, procurement, and construction) contracts were already signed, certified cost and schedule estimates were already submitted to state-level rate regulators, and long lead-time components were already being manufactured.

Instead of moving forward as planned, the Vogtle-3 & -4 and Summer-2 & -3 projects were halted while the engineers began the unpredictable process of designing a compliant shield building using modern, but not-yet-tested construction techniques.

From the moment the redesign effort started, all of the meticulously created schedules and cost estimates became obsolete. As they would say in my previous profession, they were OBE (overcome by events.)

Of course, neither the vendors, Westinghouse and Chicago Bridge & Iron (neé Shaw), nor the utility customers, Southern and SCANA, stopped moving or spending money; there was too much at stake already.

Even though all parties knew that they could not finalize the requirements for the plant's foundations until the shield building redesign was invented, tested, completed, and approved by the regulator, they could not halt site preparation or component manufacturing.

They could not stop the accumulation of ongoing interest payments on borrowed money. They could not stop construction of the training facilities or the hiring and prequalification training for future operators.

Why not correct the record?

I've spent much of the time since my visit trying to understand why no involved party has made a noticeable public effort to correct the record and explain that the delays were outside their control.

The answer I have discovered is completely unsatisfying. I asked some hard questions. Here is an example of the verbal and written replies:

"The issues raised in your questions are subjects of disputes that are currently in litigation. It is not appropriate to comment outside of the litigation process. The parties' respective pleadings in the litigation set forth their positions."

Apparently, the vendor team and the owners group would rather litigate and point fingers at each other rather than to tell a truthful story that identifies the real culprit.

Several industry experts have suggested that nuclear plant licensees are extremely reluctant to blame the regulators that still control their destiny.

It is beyond the scope of this commentary to open up the question of whether or not the Aircraft Impact Assessment rule was a reasonable response to the irrational fear induced by the events of 9/11.

It is not even my intention to question the reasonableness of applying the rule that is not required for adequate protection to projects that were already underway.

The mission of this commentary is to explain that the root cause of the schedule delays and cost increases for both the Vogtle-3 & -4 and Summer-2 & -3 projects was a national-level decision to force a substantial redesign after major project decisions had been made.

As long as the regulations do not change again, there now exist several designs that meet the new requirements. Customers that order those designs now should be able to avoid the impact of a midstream design change.

It would be in the best interests of the industry and the projects that are currently underway to make it clear that the Vogtle and Summer projects were the subject of a one-time decision.

They should not be seen as indications that the nuclear industry is incapable of achieving predictable cost and schedule performance.

____________________________

Rod Adams is a nuclear advocate with extensive small nuclear plant operating experience. Adams is a former engineer officer, USS Von Steuben. He is the host and producer of The Atomic Show Podcast. Adams has been an ANS member since 2005. He writes about nuclear technology at his own blog, Atomic Insights.

Rod Adams is a nuclear advocate with extensive small nuclear plant operating experience. Adams is a former engineer officer, USS Von Steuben. He is the host and producer of The Atomic Show Podcast. Adams has been an ANS member since 2005. He writes about nuclear technology at his own blog, Atomic Insights.