Pacific Fusion: Fusing pulser innovation with General Atomics’ expertise

.jpg)

Pacific Fusion has a staff that knows its way around pulsers and inertial fusion, and an ongoing collaboration with General Atomics. Today, the two companies are announcing plans to test Pacific Fusion’s pulser-driven inertial fusion energy concept, with commercial fusion power as the goal.

“We are building a fusion machine and testing all equipment—including components and a pulser module—at our Pacific Fusion test center,” Pacific Fusion cofounder and chief technology officer Keith LeChien told Nuclear News. “GA’s engineering expertise remains an important part of our progress, and we expect this collaboration to continue through future phases of development.”

Technical complements: Pacific Fusion is based in the Bay Area city of Fremont, Calif., where testing last winter demonstrated that components of its pulser modules met performance and reliability expectations.

Now, the company plans to test a production-scale pulser module equipped to store electrical energy in a series of staged capacitors and deliver it in precisely controlled bursts, and then build 156 such modules into a demonstration system by 2030. That’s the machine that Pacific Fusion said earlier this month it expects will achieve net facility gain—more fusion energy out than all energy stored in the system.

“Pacific Fusion is leading in pulsed magnetic fusion system design, including target physics, pulsed power, and mechanical engineering,” said LeChien. “GA has supported PF since our founding, contributing valuable engineering expertise. Their role has included system mechanical engineering analysis, benchtop prototype testing, and some infrastructure planning.”

Anantha Krishnan, senior vice president of the General Atomics Energy Group, told NN that GA’s expertise in computational modeling design, fusion science, and engineering “offers a powerful launchpad for fast-moving start-ups like Pacific Fusion.” Now that Pacific Fusion is progressing to module construction, GA’s role is expanding to include collaboration on full-scale fusion power plant components, such as system operations, cryogenics, manufacturing at production scale, and target fabrication.

General Atomics’ expertise: In San Diego, about 450 miles south of Pacific Fusion’s Fremont headquarters, GA has operated the DIII-D magnetic fusion tokamak as a Department of Energy user facility since 1986 and also worked on DIII-D’s precursors since the 1950s. GA’s fusion expertise isn’t confined to its tokamak facilities—it is supplying components for ITER and manufacturing inertial fusion targets for the laser-driven National Ignition Facility at Lawrence Livermore National Laboratory. It also described its own magnetic tokamak fusion pilot plant design in 2022.

“General Atomics has developed significant capabilities in fusion science and technology over several decades of research and development,” Krishnan told NN. “We are now applying these capabilities to help fusion energy companies tackle some of the toughest scientific and engineering challenges in achieving the goal of commercial fusion energy.”

“GA’s business model is to provide our unique technical expertise and capabilities to enable our collaborators in the fusion energy industry to successfully bring fusion energy to the market,” Krishnan added. “We work closely with a wide range of collaborators across the fusion landscape, including those focused on magnetic as well as inertial fusion.”

Pacific Fusion’s innovation: In addition to being Pacific Fusion’s cofounder and CTO, LeChien is coinventor of the impedance-matched Marx generator (IMG) that the company’s power plant concept relies on.

“The IMG was inspired by the need for a more practical, efficient, and reliable architecture for commercial fusion,” LeChien explained. “As with a traditional Marx generator, it charges capacitors in parallel and discharges them in series. In this case, its triggering matches the speed of electromagnetic waves, so energy is delivered with about 90 percent efficiency. This boosts performance while cutting the size of the fusion system in half. The IMG uses lower-voltage components and standard materials, making it safer, easier to assemble, and more cost effective. The goal was to improve fusion performance while keeping the system simple, scalable, and practical for real-world power use.”

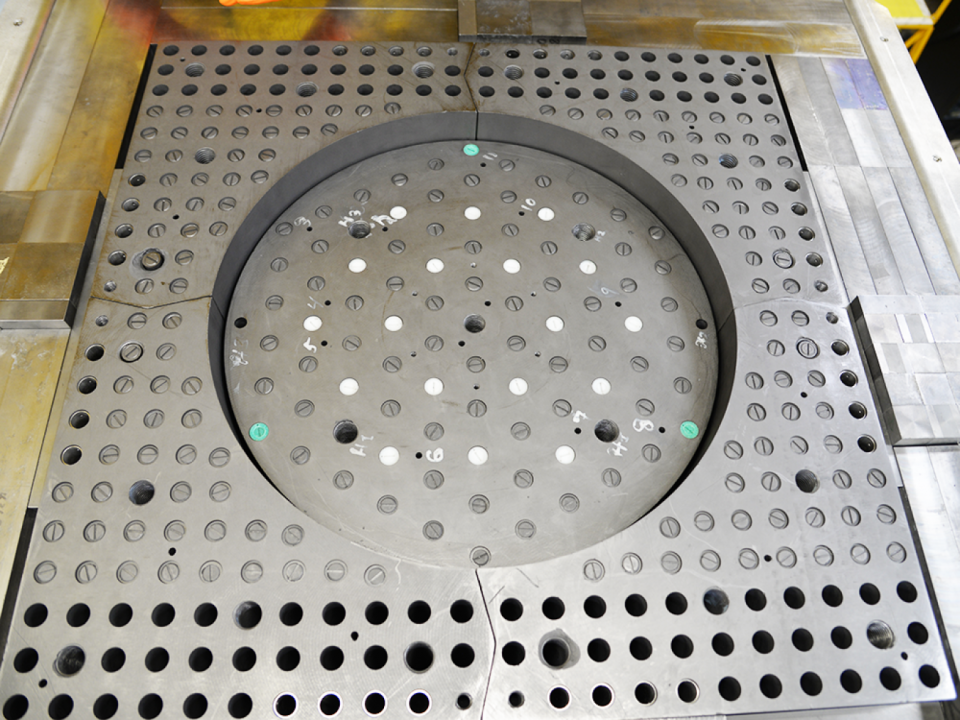

Each pulser module consists of stages (32 for the demonstration system) connected in series along a pulse tube.

LeChien inspecting a stage during assembly. (Photo: Pacific Fusion)

Each of the circular stages features multiple “bricks” (10 per stage for the demonstration system) positioned around the circumference of the stage; each brick consists of two capacitors and a switch. The electricity stored in the capacitors is released in pulses that speed through metallic pulse tubes toward the fusion chamber. The energy from multiple modules is coupled into two electrodes, which drive current through the target and electromagnetically compress it to cause fusion.

Combined power: Each pulser module has a diameter of about 1.9 meters and can deliver about 2 TW of peak power in a single fast pulse, which Pacific Fusion says is about four times more power than the average amount of power provided by the entire U.S. electrical grid. Pacific Fusion expects its demonstration system to store about 80 megajoules of electrical energy and deliver more than 60 megaamperes in about 100 nanoseconds.

By directing that energy to centimeter-scale deuterium-tritium fuel capsules, as in laser-driven inertial confinement fusion but with the ability to “magnetically squeeze” the fuel inside a meter-scale fusion chamber (surrounded by a deionized water tank for neutron shielding), Pacific Fusion’s founders believe their approach can expand the range of pressure and confinement time conditions under which fusion can be achieved.

The total footprint of the planned demonstration system is about 73 by 80 meters. As for a hypothetical future power plant, “We can tailor power plant size and capacity across a wide range, primarily by varying the designed target yield and/or repetition rate,” LeChien said. “One attractive combination would let us produce about 250 net MWe with a very compact footprint of 25 acres or less.”

Funding: A technical paper that Pacific Fusion published earlier this month on arXiv lays out the company’s case for “affordable, manageable, practical, and scalable (AMPS) high-yield and high-gain inertial fusion.”

When asked how costs are estimated and “affordable” is defined, LeChien said Pacific Fusion’s goal is “to generate the world’s lowest-cost firm power” and noted the company’s modular technology is “amenable to low-cost mass manufacturing with highly scalable supply chains.”

“We combine estimates from detailed quote-informed costs of our demonstration system with average cost estimates of other fusion-related systems—the blanket, for example—and balance of plant,” LeChien said.

It takes a good deal of money to design affordable, scalable power sources. For Pacific Fusion, that includes the $900 million of committed capital from investors, including venture capital firm General Catalyst, that was announced when Pacific Fusion emerged from “stealth mode” in October 2024. That $900 million is being released in tranches as the company reaches milestones.

In addition, LeChien said, “We’re pursuing federal funding opportunities to support our research, development, and demonstration efforts. Public-private partnerships are essential to accelerating fusion energy and building U.S. leadership in this field.”

Talent at scale: Prior to cofounding Pacific Fusion, LeChien built a career in pulsed magnetic fusion at LLNL and served as director of inertial confinement fusion at the National Nuclear Security Administration. Founding CEO Eric Lander led the International Human Genome Project and had stints as science advisor to President Biden and head of the White House Office of Science and Technology Policy. Cofounder and president Will Regan worked at the DOE’s ARPA-E to develop the Accelerating Low-Cost Plasma Heating and Assembly (ALPHA) cost-shared fusion development program. And their team is growing.

“About half of our technical team comes from the U.S. national labs, bringing deep fusion expertise,” said LeChien. “As we grow, we’re combining that foundation with talent from a wide range of fast-moving hard technology industries like aerospace and automotive. Our focus is on building a team that can move quickly, scale systems, and deliver real-world energy solutions.”