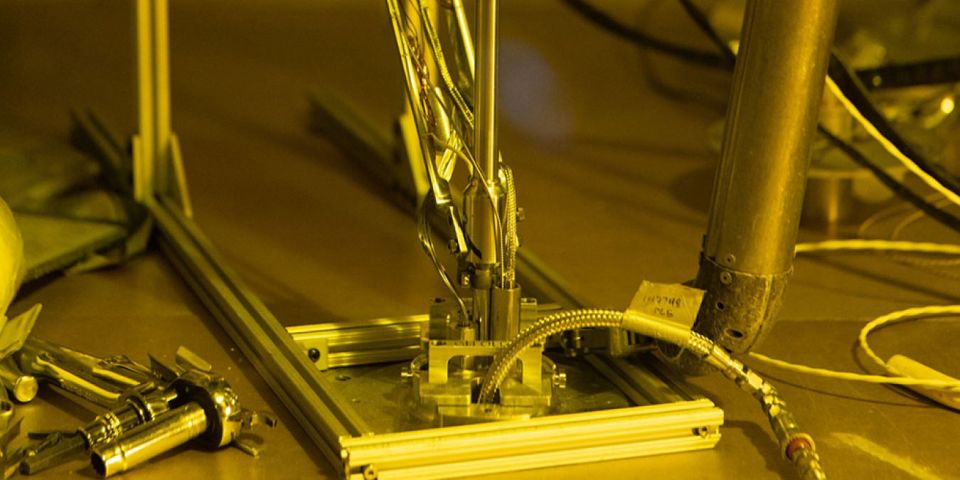

A worker replaces the end jig used to collect fuel debris samples from the damaged Fukushima reactor. (Photo: TEPCO)

Tokyo Electric Power Company is scheduled this week to begin retrieving a second sample of nuclear fuel debris from Unit 2 of Japan’s damaged Fukushima Daiichi nuclear power plant. This second retrieval comes after TEPCO improved the telescopic device used to gather samples.

In its first trial exercise, conducted in October, TEPCO retrieved a small piece (about 9 mm by 7 mm) of fuel debris from Unit 2’s pressure vessel. Preliminary nondestructive analysis of that sample found that it contained iron and uranium, along with other elements such as zirconium, chromium, and nickel, consistent with fuel cladding and structural material components. Further destructive analysis of the sample, both mechanical (solid) and chemical (liquid), is to be carried out in the coming months.

According to TEPCO, the main purpose of trial fuel debris retrieval is to obtain information on the composition of fuel debris to help in planning the large-scale removal and storage of the debris from the reactor pressure vessel. According to estimates, about 880 tons of fuel debris remain in the three Fukushima reactors that suffered meltdown.

The process: To retrieve the fuel debris samples, workers use a telescoping robotic arm that passes through a penetration of Unit 2’s primary containment vessel and through an opening in the reactor pedestal. Connected to the arm is an end jig holding a monitoring camera and mechanical gripper used to grab debris samples. The samples are retrieved from debris that collected on the pedestal floor following the reactor meltdown.

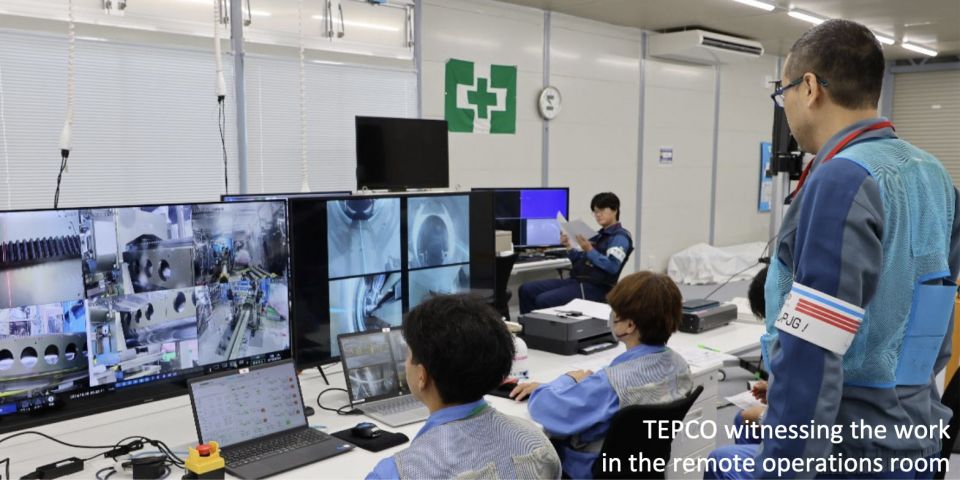

During last year’s trial, TEPCO ran into problems with the telescopic arm and monitoring cameras, which delayed the retrieval of the first sample.

For this second trial, TEPCO replaced cameras on the robotic arm and end jig and improved the design of the device. According to the company, during the first fuel debris sampling, time was needed to maneuver the end jig due to its instability. Stability was improved by moving the gripper to the center of rotation on the end jig. The size of the gripper was also increased from 5 mm2 to 7 mm2.

TEPCO said it completed the improvements to the end jig and confirmed that they were working properly on April 9. Fuel debris from a different location of the reactor floor is to be retrieved during this latest trial.