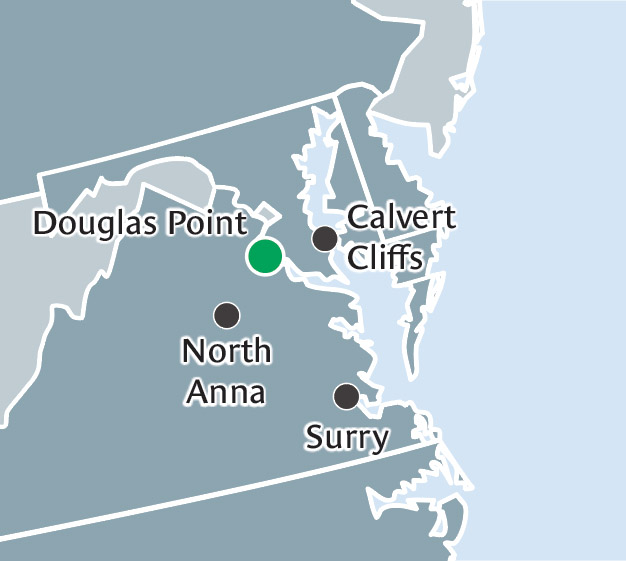

The geological conditions at Chesapeake Bay would have added significant foundation costs to the project. The additional expense associated with real estate procurement combined with impact on the population ruled out the second potential site. It was noted at the time that Douglas Point would have lower transmission costs due to its much shorter requirement for a transmission corridor tie-in to the transmission system. Thus, the focus turned toward Douglas Point as the preferred site.

In 1973, prior to the proposal for Douglas Point, PEPCO’s generation capacity was nearly 4,400 MWe. The expected development of the area required additional generation capability. An example of new development and construction at the time was the Metro subway system, which was projected to add an additional 130 MWe of load to the system that was expected to climb to 380 MWe by 1982. Planned new housing was projected to add another 1,600 MWe of load. Building and operating the new dual-unit power plant would offset predicted demand by adding 2,356 MWe of available generation.

Nuclear as the energy source was selected for many reasons, including the elimination of coal piles, dust, and other potential environmental impacts. PEPCO also cited the use of uranium that would reduce generation costs and expand PEPCO’s generation diversity.

On July 2, 1973, a construction permit was sent to the U.S. Atomic Energy Commission. Construction was to start in March 1975, with anticipated completion of the first unit in 1980. Both units were expected to be on line by 1982. Douglas Point was estimated to encompass 1,440 acres. For power generation, 290 acres would be used in the following manner: 200 acres allotted to the generating station, 30 acres for the on-site transmission right-of-way, and 60 acres for an undeveloped reserve. To protect wildlife, 180 acres of marshland and an additional 690 acres were to be left undisturbed. In addition, 140 acres were to be set aside for recreation, and 10 acres were allotted for ecological education.

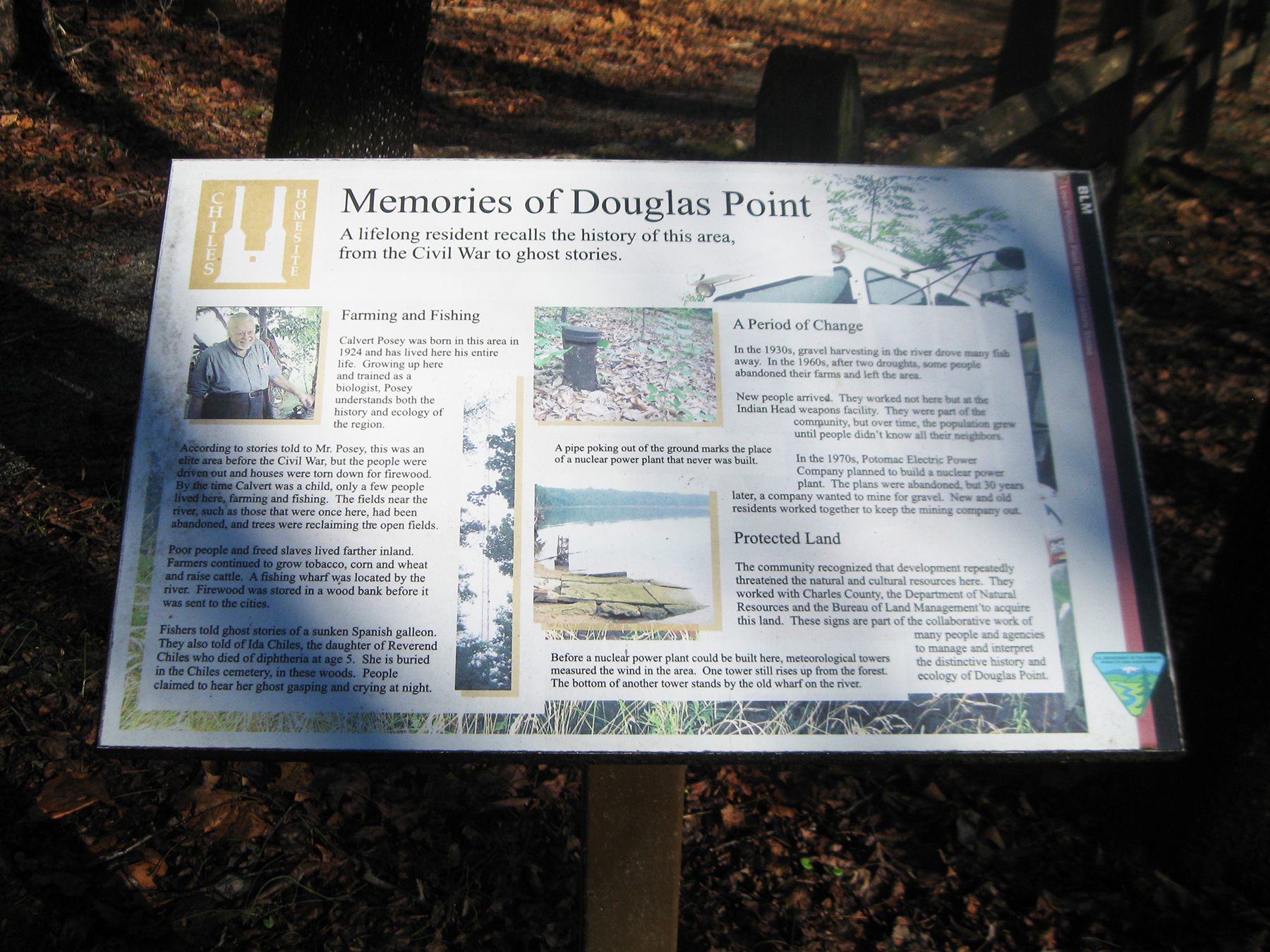

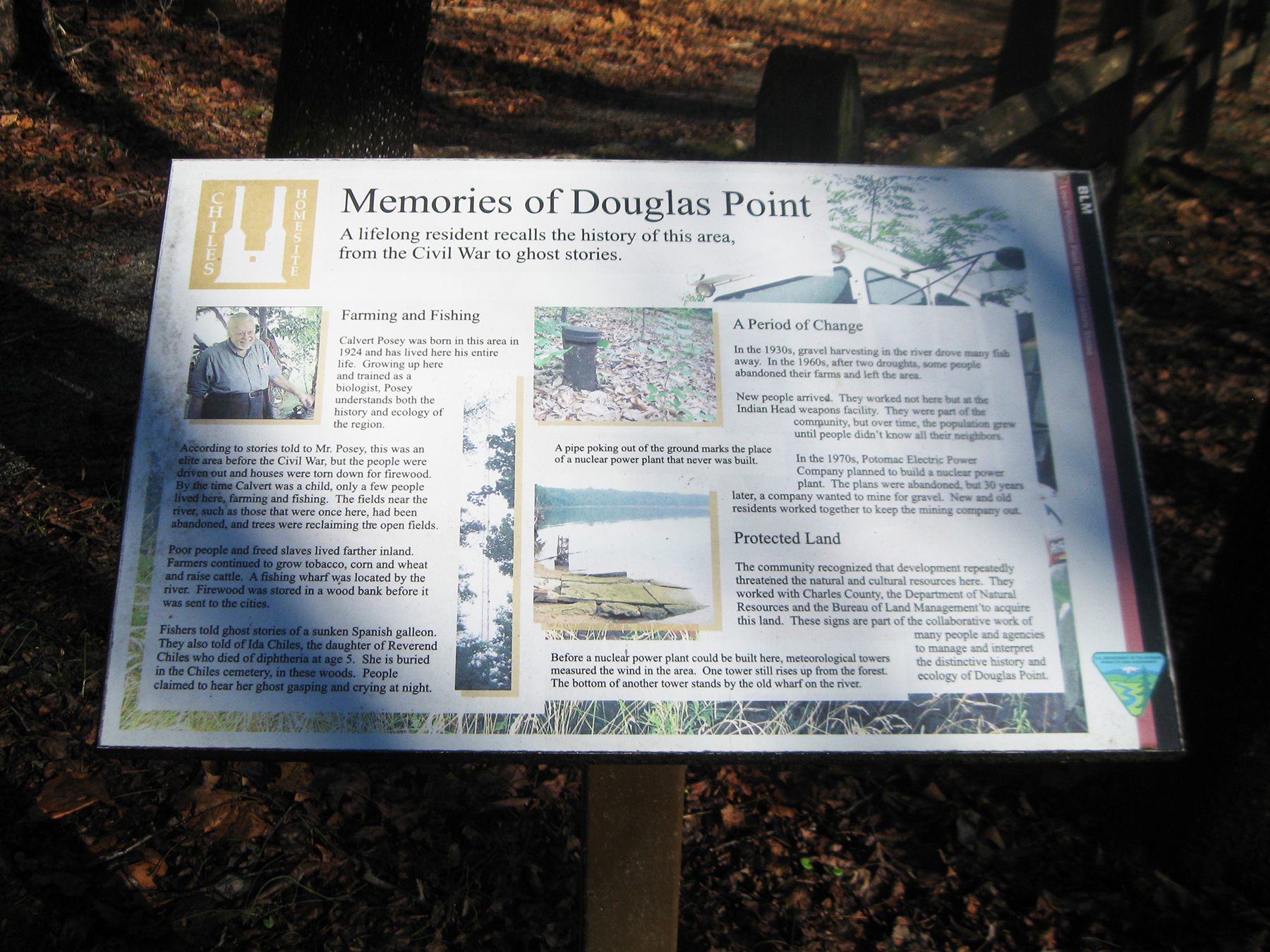

The only evidence of Douglas Point nuclear power plant in Maryland is a lone pipe protruding from the ground, as shown on this marker recounting the history of Douglas Point in Maryland. (Photo: National Park Service)

The latest reactor design at the time, the General Electric BWR/6, was selected by the utility for the new power plant. It had a reactor assembly height of nearly 84 feet and contained 732 fuel assemblies and 177 control rods. The more power dense BWR/6 introduced some upgrades to its predecessor, the BWR/5. Active fuel length increased from 144 inches to 148 inches, the use of a new “water rod” was introduced, and 8×8 fuel bundles were incorporated, replacing the 7×7 design. There were also efficiencies in control blade thickness, steam separator design, and jet pump nozzles, to name a few.

The reactor was to be housed in the new Mark III containment building. It was more compact, compared with prior containment designs, yet had improved seismic ratings and reduced proposed dose levels during accident modeling. The steel containment vessel was to be surrounded by three-foot-thick walls that provided radiation shielding. A drywell constructed with reinforced concrete would surround the reactor vessel, providing a pressure boundary during a loss-of-coolant accident.

Douglas Point’s proposed control room had many features that were improvements over the control rooms already in use at the time. It was designed to increase operator awareness of plant conditions and reduce the physical operating area. It was even proposed that digital systems with cathode ray tubes (CRTs) for display would be incorporated.

The goal of increasing operators’ awareness was to be achieved by reducing the total number of components (controls and displays) that the operator had to use to control the reactor. By reducing the number of components, the footprint of the control room would simultaneously be reduced. The CRT displays would increase operators’ comprehension of plant conditions by providing indicators using color-coded references. In addition, to assist in operator comprehension, designers avoided layouts that provided multiple rows of controls or indicators that were not immediately distinguishable.

Much consideration was given to control room design and layout. Each unit was to have its own set of operating boards, as well as a separate board for each unit’s safety and shutdown systems. The central board for each unit was to provide reactor control, the left board would provide control over nuclear steam supply, and the right board would provide control over balance-of-plant components. There was also to be a common board for systems that both units would share. In addition, there would be a supervisory console that could be used to monitor plant operating conditions without interrupting plant operations. This console was designed to have two color CRT displays and a keyboard.

Douglas Point was to employ two state-of-the-art computer systems—one for each unit. Significant efforts were made to ensure the accuracy of the information presented on the CRT displays. To ensure that information was as error-free as possible, a system was to be incorporated to provide feedback to the unit operator indicating the status of the CRT computer system.

The power plant was set to be a technologically advanced reactor serving the needs of the nation’s capital and surrounding area. However, these plans never came to fruition. According to the Chesapeake Bay Journal, “Local residents fought the power plant, arguing that the facility could, among other things, interfere with striped bass spawning in the river. PEPCO scuttled its plans in the late 1970s.” In addition, the anticipated population increase of the Washington D.C. area during the second half of the 1970s weakened, and with it, some of the anticipated demand for power. Ultimately, the need to spend capital on Douglas Point dissipated, and the plans were scrapped.

Jeremy Hampshire is an ANS member whose avocation is writing about the history of nuclear science and technology. His experience includes time as a lead nuclear quality assurance auditor and a senior nuclear technical advisor.

-3 2x1.jpg)