West Valley shares 3D model and lessons learned

A virtual meeting between representatives of the West Valley Demonstration Project (WVDP) in New York and the Oak Ridge Office of Environmental Management (OREM) in Tennessee was held recently to share lessons learned from the ongoing demolition of West Valley’s main plant process building.

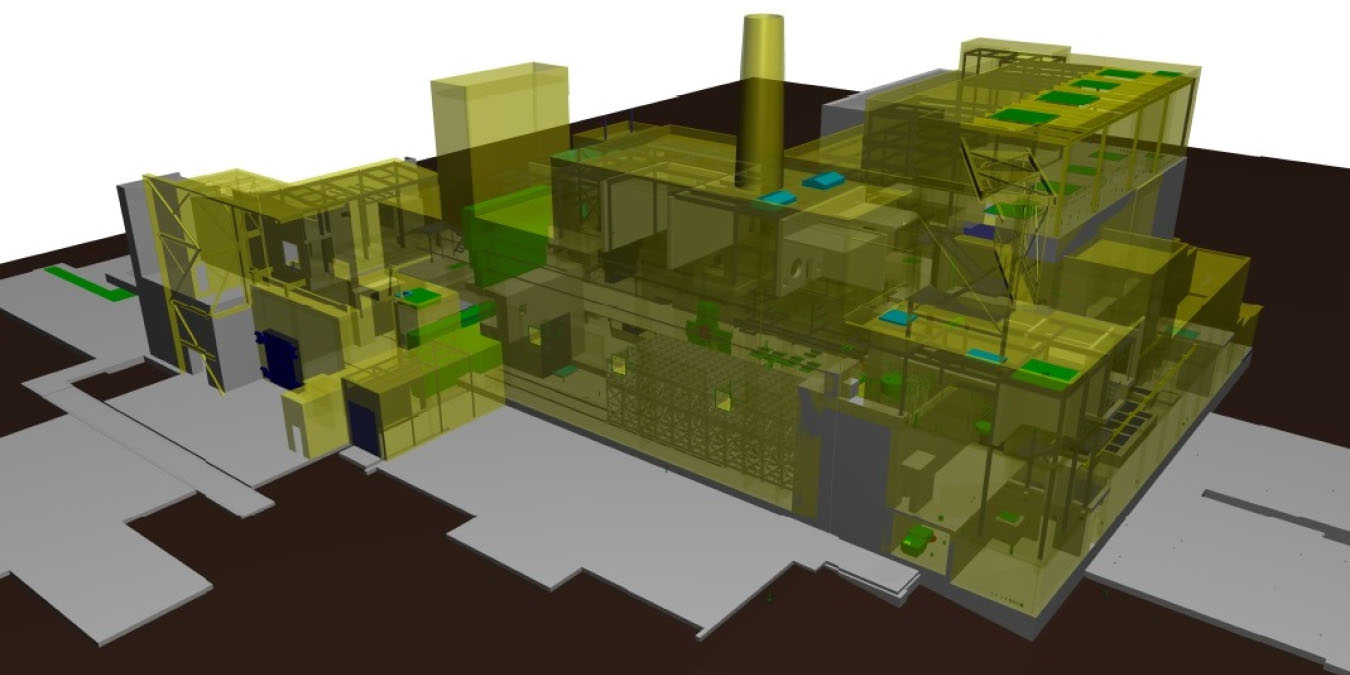

The focus was on WVDP’s 3D model of the main plant. The model is a tool of the Department of Energy’s Office of Environmental Management that illustrates sections of the plant, from walls and support beams to equipment and piping. To date, 85 percent of the main plant’s deconstruction has been completed.

Created with the help of WVDP onsite engineers and an outside company prior to the start of the demolition, the 3D model was used to determine the rate and sequence that work crews would take down the main plant. According to the DOE, the project has been successful so far, with no incidents, unplanned releases, or injuries.

Workers at the West Valley Demonstration Project use the site’s 3D model at pre-job briefings each workday to prepare for demolition activities. (Photo: DOE)

Closer look: The model showed the locations of more than 120 items requiring special handling and packaging. It also pinpointed multiple areas of specialty piping with high radiation potential and hazardous asbestos-containing material. Crews applied all required safety measures for that material. Engineers used the model to evaluate the plant’s walls, components, structural members, and obstructions, allowing for an analysis of structural integrity and hazard points as the demolition sequence unfolded.

The above-grade portion of the main plant is one of the last major facilities remaining at WVDP. Its successful demolition will further reduce environmental risks and position the site for the next phase in cleanup. The demolition is expected to be completed this fiscal year, which ends September 30.

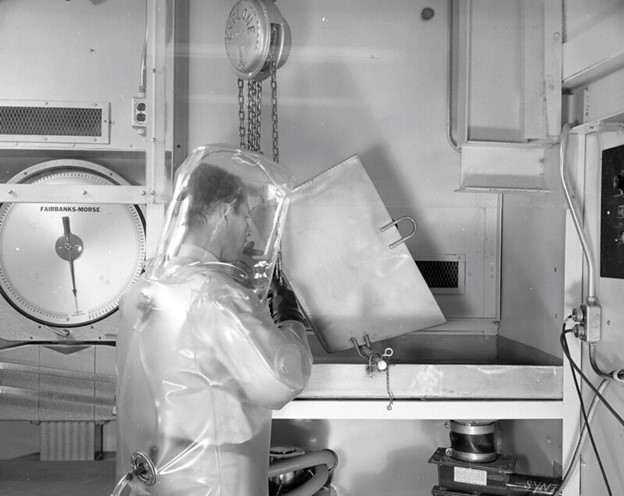

About West Valley: WVDP, 35 miles south of Buffalo, N.Y., is an approximate 150-acre site that is owned by the New York State Energy Research and Development Authority. It is home to the only commercial spent nuclear fuel reprocessing facility to operate in the United States.

In production from 1963 to 1972, the site processed 640 metric tons of spent fuel and generated more than 600,000 gallons of liquid high-level waste. In 1980, Congress passed the WVDP Act, which required the DOE to conduct a waste management demonstration project at the site and transport the waste to a federal repository for disposal. Currently, the waste, after being solidified into glass canisters, is stored onsite in concrete vaults, awaiting permanent disposal at a future federal repository.

Tennessee work: OREM is taking down excess contaminated facilities across the Oak Ridge Reservation, which eliminates risks and opens land for reuse to support research and national security missions. Teams are set to demolish the final hot cell this year at the former Radioisotope Development Laboratory at Oak Ridge National Laboratory. Work will be done to prepare more than a dozen facilities for future demolition, a list that includes the Oak Ridge Research Reactor, Graphite Reactor support facilities, and Isotope Row facilities at ORNL.

Quotes: Evan Koelker, a Savannah River National Laboratory senior scientist, noticed an abstract submitted to this year’s Waste Management Symposia on WVDP’s 3D model and thought information about the technology would be useful for his colleagues at OREM. He contacted West Valley to help schedule a meeting to learn more about the 3D model. “Being able to share experiences, expertise, and lessons learned is an important element in being a learning organization,” said Koelker. “Obtaining information and lessons learned from a successful project is a formula for success and ensuring that information is available for future teams and projects is a formula for progress.”

Neil Armknecht, facility disposition engineer with WVDP cleanup contractor CH2M HILL BWXT West Valley (CHBWV), said West Valley is happy to share its lessons learned in support of similar risk-reduction activities at Oak Ridge. “The open exchange of information and collaboration among the sites benefits cleanup efforts across the DOE complex,” Armknecht said.

Daniel Hurst, a project engineer with OREM contractor UCOR, believes that sharing information is vital to success. “When one site has figured out how to perform work safer and more efficient while maintaining environmental compliance, it needs to be shared across the complex for continuous improvement,” Hurst said. “For us at UCOR, we have a specific need to use what West Valley has done to better plan and execute some of our future characterization work. Finding better ways to perform cleanup activities now is important to help our current and future workforce and protect the public for generations to come.”

Gaining insight from lessons learned is not a one-time activity, said Jason Casper, CHBWV president. “Our learning has not stopped. It continues everyday as we perform cleanup efforts to reduce legacy risks as we learn from other sites,” he said. “OREM and WVDP, along with other sites, will continue to share lessons learned and best practices for the benefit of our employees, the general public, the taxpayer and the environment.”