Nuclear materials testing project brings U.S. and U.K. expertise together

As nations look to nuclear energy as a source of reliable electricity and heat, researchers and industry are developing a new generation of nuclear reactors to fill the need. These advanced nuclear reactors will provide safe, efficient, and economical power that go beyond what the current large light water reactors can do.

But before large-scale deployment of advanced reactors, researchers need to understand and test the safety and performance of the technologies—especially the coolants and materials—that make them possible.

Now, the United States and the United Kingdom have teamed up to test hundreds of advanced nuclear materials.

NNUF leadership poses with both the UKAEA assembly team and INL design team members at the Materials Research Facility after witnessing the final assembly of NIFT-E. (Photo: INL)

Researchers from the U.K. National Nuclear User Facility (NNUF) are collaborating with the U.S. Department of Energy Office of Nuclear Energy’s Nuclear Science User Facilities (NSUF) program on the Neutron Irradiation as a Function of Temperature–Experiment (NIFT-E). The collaboration also includes several national laboratories, universities, and companies in the United States and Britain (see sidebar on page 29).

The experiments, which will test 578 advanced metal and graphite materials in INL’s Advanced Test Reactor (ATR), are part of the U.S.-U.K. Nuclear Energy Research and Development Cooperative Action Plan. Signed in 2018, the plan is designed to foster nuclear energy research coordination between the two countries.

NIFT-E is the brainchild of Chris Grovenor, professor of materials at Oxford University and chair of the NNUF management group, and Rory Kennedy, former NSUF director and current Nuclear Science and Technology Directorate fellow and director of the Glenn T. Seaborg Institute at Idaho National Laboratory.

Material specimen suppliers

- Westinghouse Electric Company

- Oak Ridge National Laboratory

- U.K. National Nuclear Laboratory

- Pacific Northwest National Laboratory

- Purdue University

- Oxford University

- University of Manchester

- Manchester Metropolitan University

- University of Sheffield

Collaborators

- Nuclear Science User Facilities

- Idaho National Laboratory

- U.K. Atomic Energy Authority

- Westinghouse Electric Company

- Oak Ridge National Laboratory

- U.K. National Nuclear Laboratory

- Pacific Northwest National Laboratory

- Purdue University

- Oxford University

- University of Manchester

The researchers hatched the collaboration after a conference in England.

“Kennedy said, ‘We ought to be doing something more than just information exchange,’” Grovenor said. “We decided on a bold initiative, a joint irradiation campaign, and to go back to our teams to get things started.”

A long history of nuclear innovation

In the years following World War II, the United Kingdom and the United States established themselves as major nuclear power innovators.

The U.K. built 41 commercial reactors, most of which were gas cooled, which required a special knowledge of nuclear materials, especially graphite. They also developed cutting-edge research facilities and capabilities. U.K. researchers still rank among the world’s leading developers of nuclear science and technology.

In the U.S., the nuclear energy industry focused on commercializing light water reactor technologies, which require their own special expertise, capabilities, and materials.

The two nations assisted each other through joint research projects, information exchanges, and sharing of capabilities. “The U.S. and U.K have collaborated in the development of nuclear power before, and there are a lot of common interests,” said Brenden Heidrich, director of the NSUF.

Materials science with mutual benefit

Dimensional inspections being performed on half of a Zircaloy fixture body via a coordinate measuring machine. (Photo: INL)

Benefits from the project flow both ways. While the U.S. team brings a wide range of irradiation and postexamination capabilities, the U.K. has some of the world’s leading nuclear materials experts—especially when it comes to graphite and other materials that will be used in advanced reactors.

“With the U.S. developing TRISO fuel and the associated advanced reactors, there is significant interest in graphite here,” Heidrich said. “Most of the advanced reactors are going to run at higher temperatures for better efficiencies. In the case of graphite, we’re getting access to some of their long experience and expertise in that area.”

The U.K. Atomic Energy Authority also fabricated standardized, high-quality ATR test capsules that will house the specimens inside the test reactors.

“It’s a complex endeavor to make these high-quality test capsules,” Heidrich said. “The standardized design is something we wanted to do for a long time. The physical design of the capsule is going to be fixed. It is intended to be a more efficient methodology to do nuclear energy materials irradiations. The old way of doing things is to almost start with a blank sheet of paper and give the team a lot of freedom to design something. What we’re saying is, ‘We’re building a box. If it can fit inside the box, it can fit into NIFT-E.’”

“The NIFT-E project will generate hundreds of these specimens,” Heidrich continued. “So we can test a dozen different material formulations in the same capsule.”

With the combination of accomplished materials scientists from the U.K. and the U.S., the irradiation and examination capabilities at INL, and dozens of samples provided by some of the world’s leading nuclear science institutions, the collaboration could yield some significant results.

The project will run for several years and will provide the first irradiation data on some novel materials as well as the first high-dose irradiation data on others. “There are a bunch of different graphite formulations and irradiation conditions that we really don’t have a lot of data on,” Heidrich said.

More than data

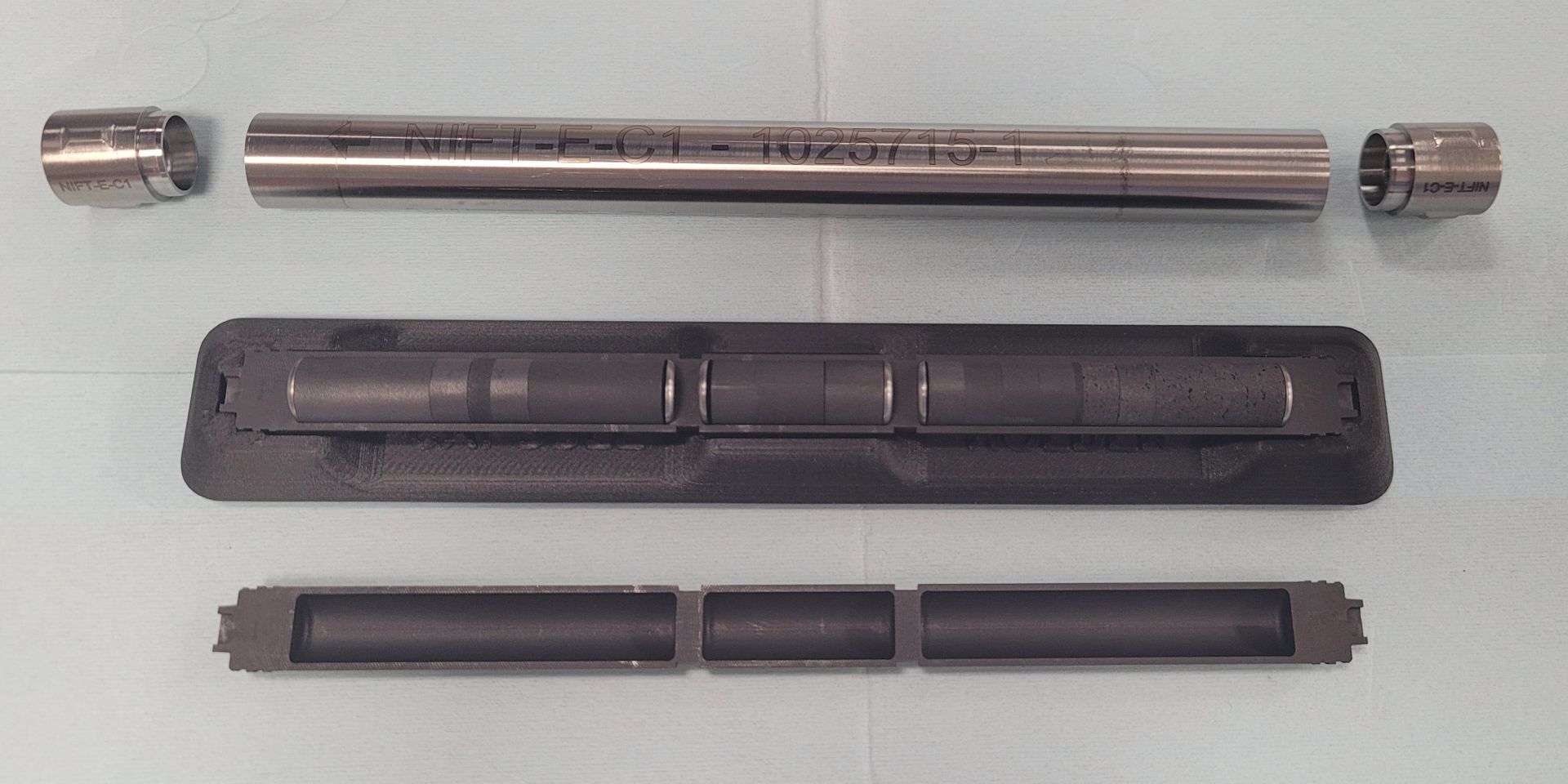

Three fully assembled NIFT-E capsules, with one NIFT-E capsule fully loaded with specimens and instrumentation, waiting for final assembly inside the Materials Research Facility located at the UKAEA. (Photo: INL

“While the collaboration will yield reams of data about materials destined for next-generation reactors, for the U.K., it will also help develop the next generation of nuclear scientists and engineers,” said Grovenor.

In the U.K., the collaboration is enhancing efforts between established research organizations such as the U.K.’s National Nuclear Laboratory, the UKAEA, and several universities that aim to bring new talent into the British nuclear energy industry. Graduate students at U.K. universities have been helping to prepare samples for the irradiation campaign.

“They’re all really up for this,” Grovenor said. “They’re saying, ‘I’m sticking around in this field because there seems to be some interesting science going on.’”

A wide range of materials

A 9-mm-diameter graphite can (lid and holder) that was used to separately contain pyrolytic carbon (PyC) and highly oriented pyrolytic graphite (HOPG) specimens from other graphite specimens within the graphite capsule. Currency from the U.S. and the U.K. shown for scale. (Photo: INL)

3-mm-diameter ferritic-martensitic steel specimens with special coatings applied provided by the U.K. NNL. (Photo: INL)

The samples represent a wide range of materials being considered for advanced nuclear reactors. Fine- to medium-grain graphite and alumina-forming austenitic (AFA) steels make up the bulk of the samples. (“Austenitic” refers to the crystalline structure of a particular type of stainless steel.)

The University of Manchester and the NNL machined the samples to their final test geometries. The samples will be irradiated at various doses at temperatures up to 750°C, the temperature components would experience in an advanced graphite-moderated, high-temperature, gas-cooled reactor.

Oak Ridge National Laboratory and Westinghouse Electric Company provided most of the AFA stainless steel samples. These alloys have been proposed for some advanced reactors, including lead fast reactors.

Other sample types include iron-chromium-aluminum (FeCrAl) alloys and a ferritic martensitic stainless steel. The atoms of these steels have a different packing arrangement, compared with austenitic stainless steel. “It changes the way the ‘marbles are packed’ to change the mechanical and corrosion performance,” explained Simon Pimblott, laboratory fellow and chief scientist in the Nuclear Science and Technology directorate at INL.

The NIFT-E project will also evaluate Grade 91, an advanced steel that was additively manufactured (3D printed) to test the effects of the special microstructure achieved by additive manufacturing on performance under irradiation.

“You can build on paper the best reactor in the world, and you can operate it at any temperature with any coolant,” said Kennedy. “Unfortunately, paper reactors don’t generate energy. You have to build them, and you have to build them out of something.”

“It could be an already employed material, but maybe there’s a new way to fabricate parts using advanced manufacturing that makes the process less expensive and faster,” Kennedy continued. “The materials could also be brand new. Regardless, they all must go through rigorous testing.”

Testing the samples

A NIFT-E capsule after a successful weep hole weld inside a weld glove box filled with a specific gas mixture blend. NIFT-E capsules are filled with different gases to aid in achieving varying temperature requirements. (Photo: INL)

All eight fully assembled and welded NIFT-E capsules, five of which are specific to alumina-forming austenitic steels, and three specific to graphite specimens. (Photo: INL)

After the U.K. team fabricated the capsules, stacked the samples in the capsules, and welded the capsules closed, they were shipped to INL for insertion into the ATR. The capsules were to undergo their first cycle of irradiation as of late 2024.

After the capsules are irradiated, they will be transported to the Hot Fuel Examination Facility at INL’s Materials and Fuels Complex. There, experts will disassemble the capsules and remove the samples for postirradiation examination by U.S. and U.K. researchers. Most of the samples will be publicly available through the Nuclear Fuels and Materials Library (NFML) and will be available to all NSUF users to propose future postirradiation experiments. This will provide an opportunity for widespread user access to these irradiated advanced reactor materials.

“These international collaborations are very important because everybody has limited resources, and expertise and capabilities are spread around our allies,” Kennedy said. “I enjoyed working with my British colleagues, and I miss our interactions. It’s an excellent collaboration, and it’s a strong contribution to the U.S.-U.K. Action Plan.”

Researchers from both sides of the Atlantic said they have rarely seen a joint project like this attacked with such vigor.

“The support and enthusiasm and engagement from our U.S. colleagues has been tremendous,” Grovenor said.

Cory Hatch is a science writer for Idaho National Laboratory.

About Idaho National Laboratory: Battelle Energy Alliance manages INL for the U.S. Department of Energy’s Office of Nuclear Energy. INL is the nation’s center for nuclear energy research and development, celebrating 75 years of scientific innovations in 2024. The laboratory performs research in each of the DOE’s strategic goal areas: energy, national security, science, and the environment. For more information, visit www.inl.gov. Follow us on social media: Facebook, Instagram, LinkedIn, and X.