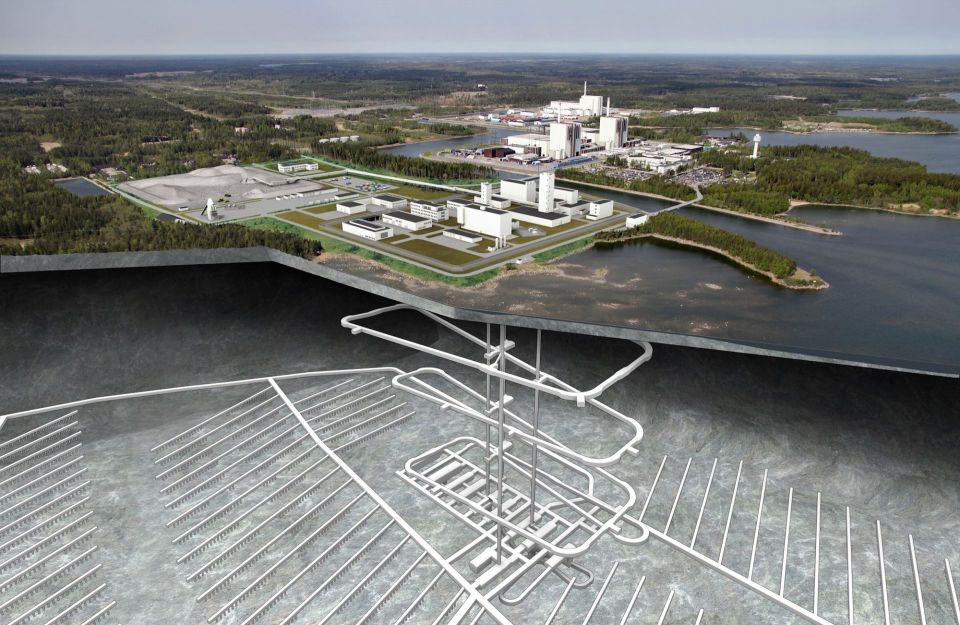

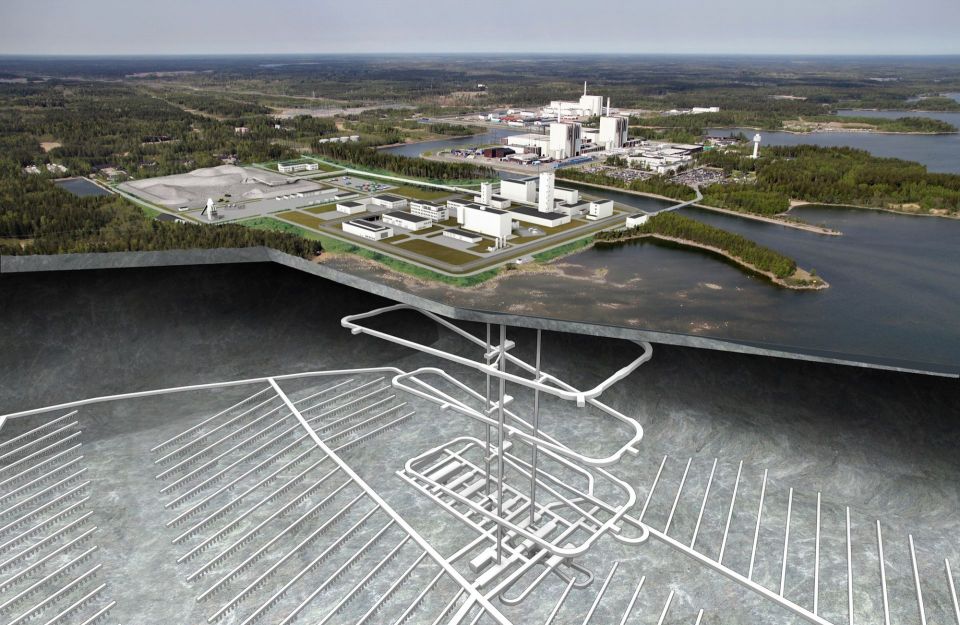

Oskarshamn nuclear power plant in Sweden. (Photo: Daniel Kihlgren)

Germany’s NUKEM Technologies Engineering Services GmbH, in partnership with Uniper Nuclear Services GmbH (UNS), has successfully completed the dismantling of the fourth and final reactor pressure vessel (RPV) at Oskarshamn nuclear power plant in Sweden. The work was done as part of the UNNU Consortium, which since 2020 has been dismantling Sweden’s four RPVs—two at the Oskarshamn site and two at the Barsebäck nuclear plant site.

As the consortium lead, UNS managed the post-segmentation and packaging of the cut RPV components into specialized containers for disposal while NUKEM conducted the in-situ segmentation of the RPV and removal of asbestos insulation between the RPV and the reactor’s biological shield.

The two boiling water reactor units at Barsebäck, which had a combined capacity of 1,215 MWe, were shut down in 1999 (Unit 1) and 2005 (Unit 2). Oskarshamn Unit 1 (473 MWe) was shut down in 2017 and Unit 2 (638 MWe) shut down in 2016. Oskarshamn-3 (1,400 MWe) is still in operation. All three Oskarshamn units are BWRs.

The process: According to NUKEM, the segmentation and packaging of the RPVs incorporated state-of-the-art technology, including a specially developed flame-cutting method and innovative tools that enabled safe handling of radioactive materials while ensuring the safety of the project team. Additional challenges, such as the removal of asbestos-containing insulation, were systematically addressed through comprehensive planning and design, the company added.

Quote: According to NUKEM, the project’s success reflects the company’s meticulous planning and extensive dismantling expertise.

“By systematically applying lessons learned, we reduced the dismantling time by nearly half from the first to the fourth reactor, demonstrating a remarkable increase in operational efficiency,” said Sergey Molodtsov, NUKEM managing director of operations.